The absolute measuring system BML SL1 works highly dynamically with a

permitted traversing speed of up to 10 m/s

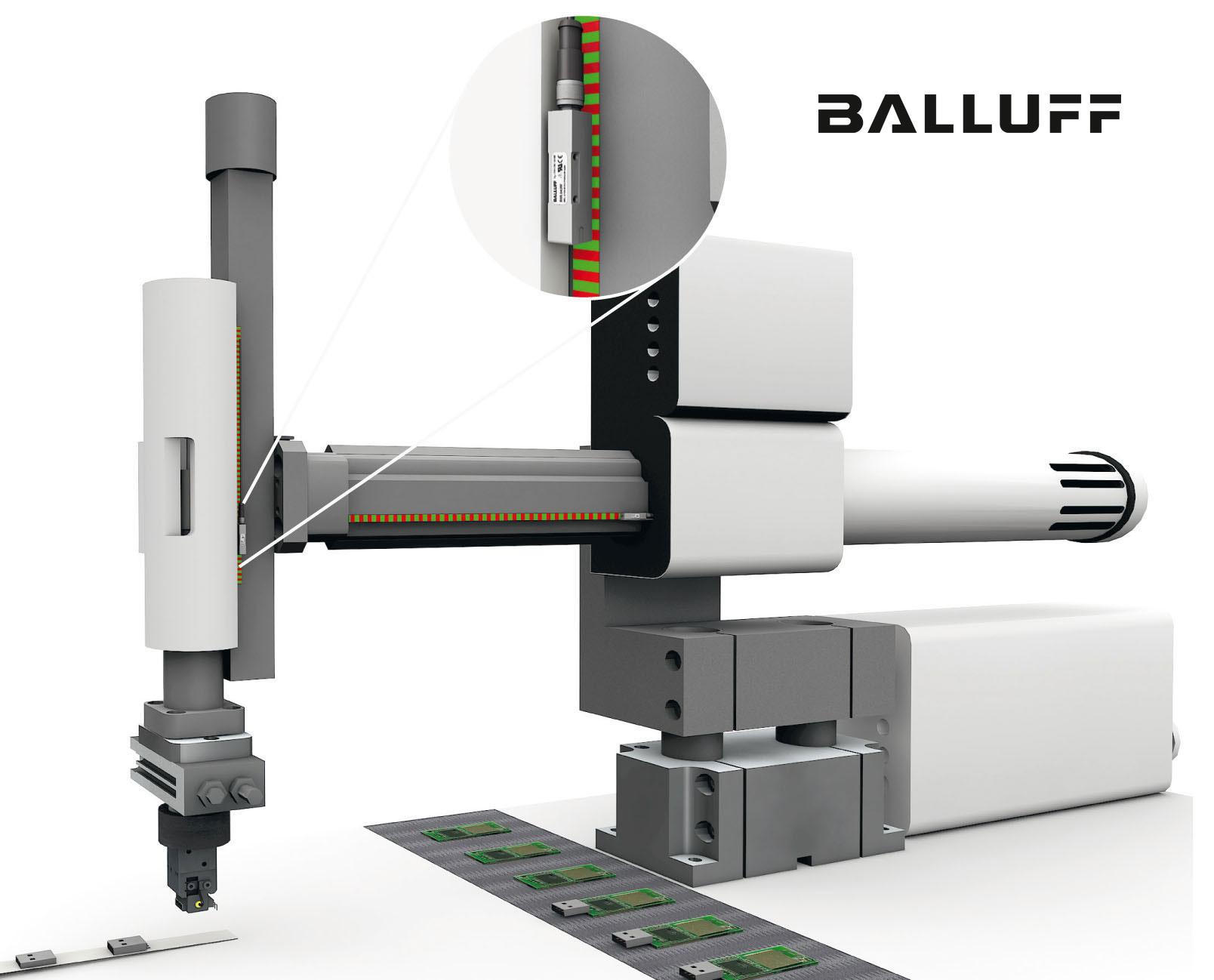

This magnetically coded system is a simple and economical solution for countless tasks, such as in factory

automation, metalworking or in the packaging field, to name just a few industry sectors. The position

information is conveniently output through the integrated IO-Link interface. The user also benefits from the

typical IO-Link features like comprehensive parameterizing and diagnostics functions, which ensure fast startup

and convenient error detection for high system availability. Even rapid format changes when a recipe is changed

can be easily accommodated. And even after a power failure and restart, the absolute position value remains

immediately available – without the need for homing. For closed-loop applications there is also an optional

interface with an incremental analog signal.

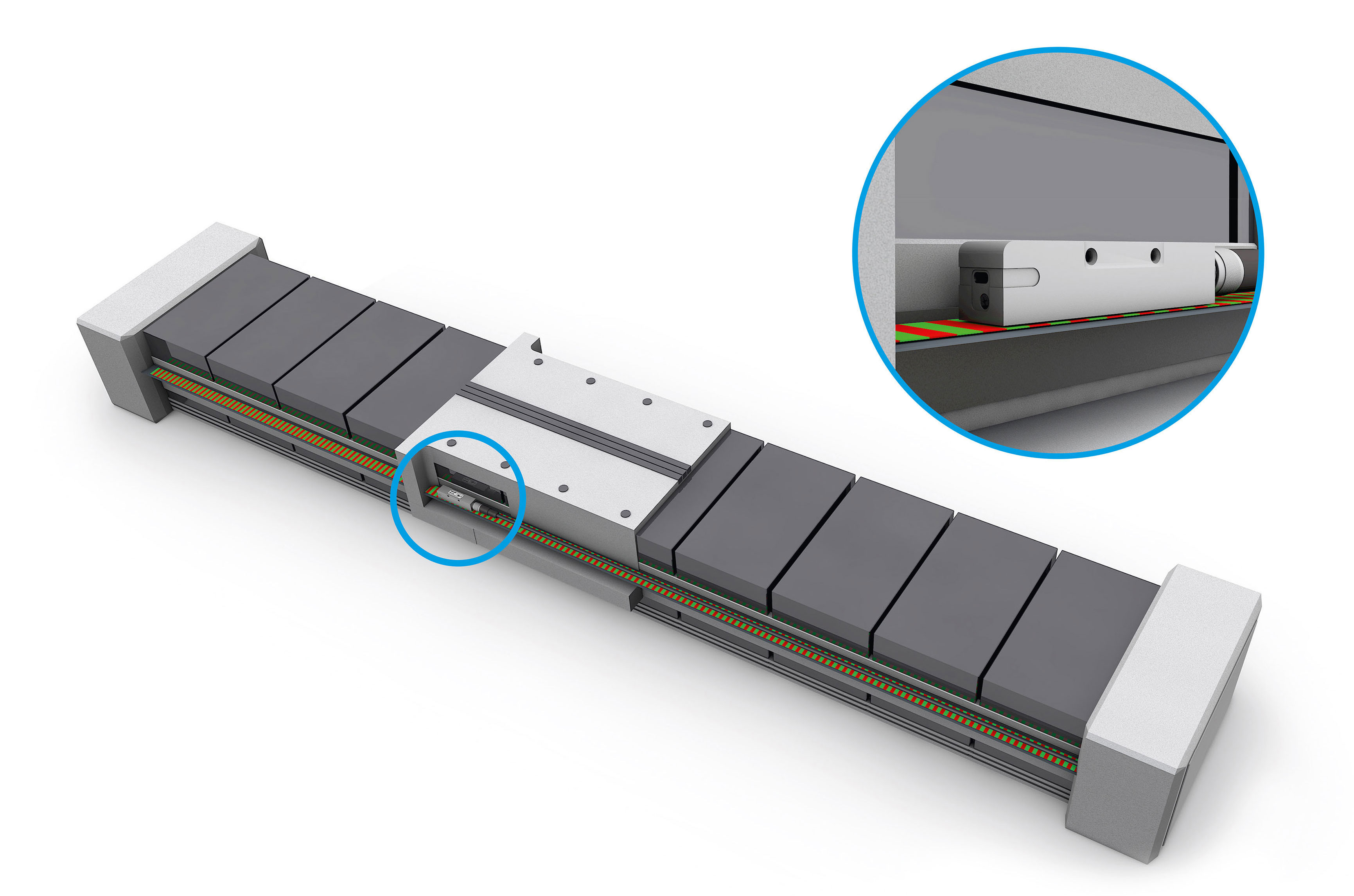

BML application: In order to record the axis movement, the sensor head

(see circle) is guided contactlessly over the measuring body

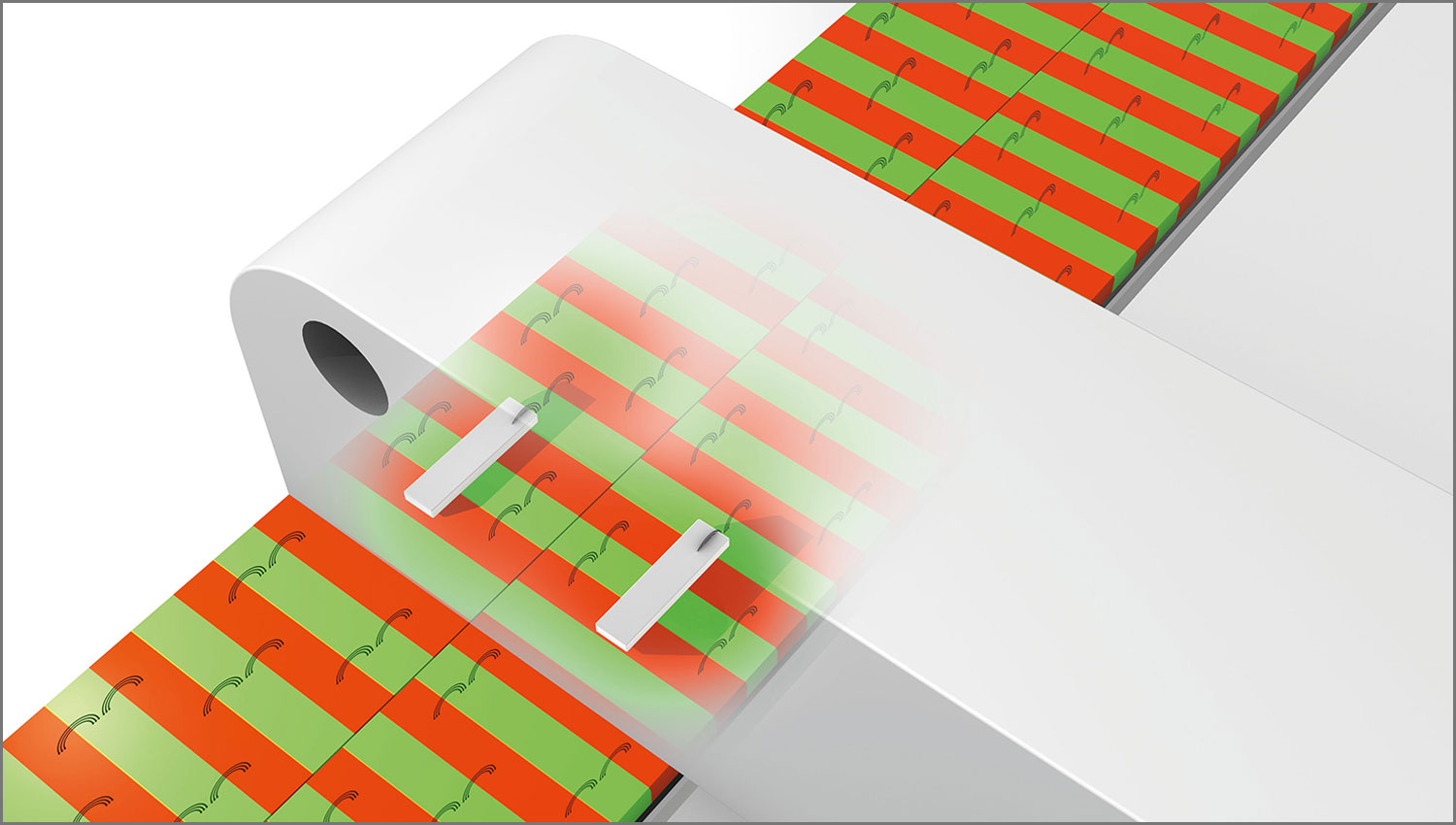

Operating principle: The system consists of the sensor head, a magnet-coded

measuring body, optionally for linear or rotary use. In order to record the position information, the sensor

head is guided contactless over the magnetized measuring body. The measuring method works without mechanical

wear and tear