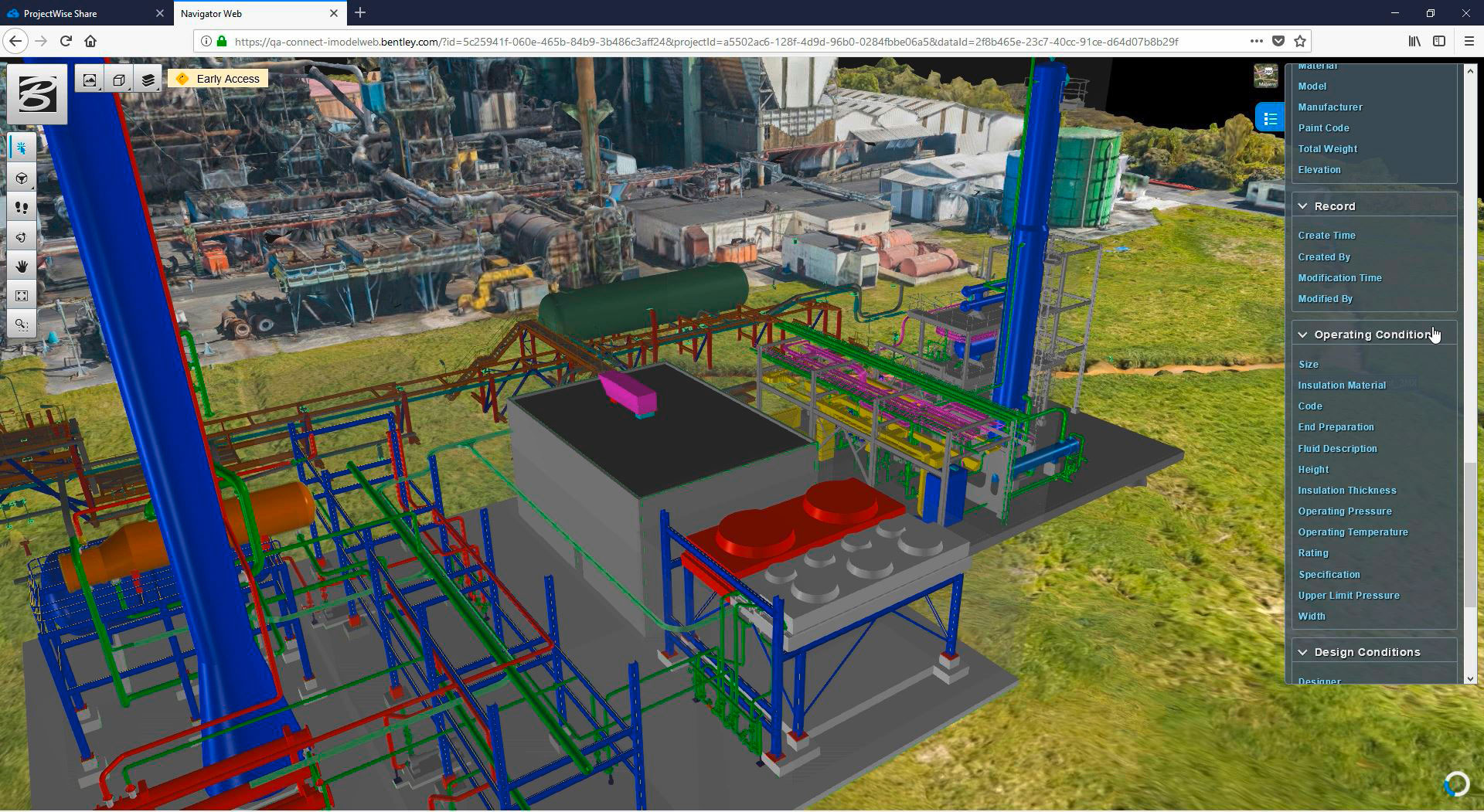

PlantSight brings together data from multiple sources including reality meshes in the

one portal view, allowing rapid access to information that has previously been inaccessible (Copyright:

Image Courtesy of Bentley Systems)

PlantSight's CDE is also populated by pertinent data from other sources, such as project deliverables and

control systems inputs, to the degree referenced through digital component tags.

PlantSight, through its new cloud service and web interface, takes advantage of the complementarity, proven engineering robustness and intelligence of Comos and OpenPlant, fully integrating functional and spatial modeling. For the first time, engineers on site can have both accessible existing data, and accessible tool interfaces, to assure that as-operated changes are timely and accurately captured and managed through PlantSight's ledger of changes, for assured fidelity. PlantSight digital twin cloud services will be marketed separately by both Siemens and Bentley, and early adopters are now being selected. The companies are now working to add to PlantSight state-of-the-art asset performance modeling (APM) capabilities, to make the most of services based on Siemens' MindSphere IoT operating system. For manufactured digital components, Siemens' Teamcenter PLM will provide immersive access to product digital twins for simulation and remediation. ▪ ds

PlantSight, through its new cloud service and web interface, takes advantage of the complementarity, proven engineering robustness and intelligence of Comos and OpenPlant, fully integrating functional and spatial modeling. For the first time, engineers on site can have both accessible existing data, and accessible tool interfaces, to assure that as-operated changes are timely and accurately captured and managed through PlantSight's ledger of changes, for assured fidelity. PlantSight digital twin cloud services will be marketed separately by both Siemens and Bentley, and early adopters are now being selected. The companies are now working to add to PlantSight state-of-the-art asset performance modeling (APM) capabilities, to make the most of services based on Siemens' MindSphere IoT operating system. For manufactured digital components, Siemens' Teamcenter PLM will provide immersive access to product digital twins for simulation and remediation. ▪ ds

Find out more now!

- Siemens Process Industry and drives

- ARC Whitepaper: Bentley’s and Siemens’ Vision for Cloudbased Distributed Engineering and Operations

- Bentley Systems

- Siemens at the sps ipc drives 2018

sps ipc drives 2018 – Hall 11

2018, November 27 – 29