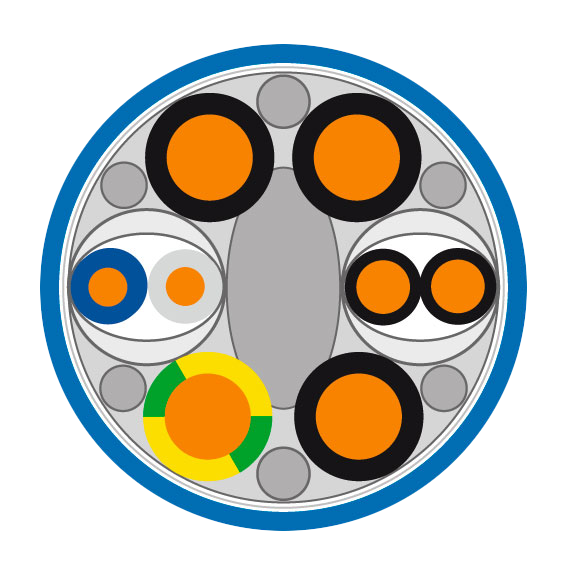

Typical cable structure for single cable

interfaces

Just five years ago, a motor with encoder and the associated drive (used here as a general term to describe

drive control, drive, servo controller, servo drive, frequency converter etc.) were usually connected using two

cables. This allowed for the reliable separation of data and power. However, this also involved increased space

and material requirements, as well as some additional costs during production and installation. Single-cable

installations are the more cost-effective alternative. This development was also accelerated by the HIPERFACE

DSL

® and SCS open link protocols, which are based on the RS485 transmissions standard. The cable

manufacturers

developed suitable hybrid shield-in-shield motor cables with one external shield and multiple internal shields.

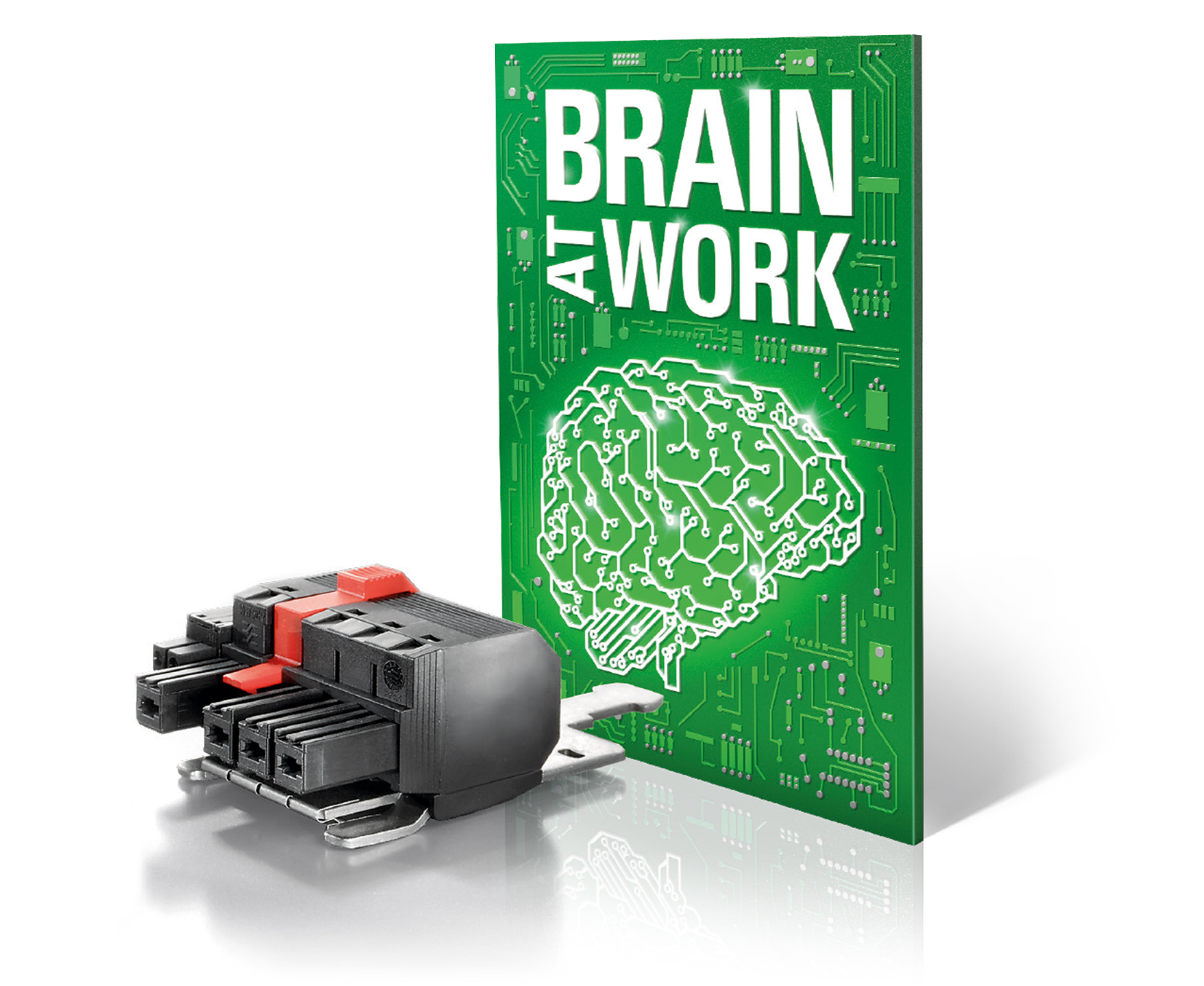

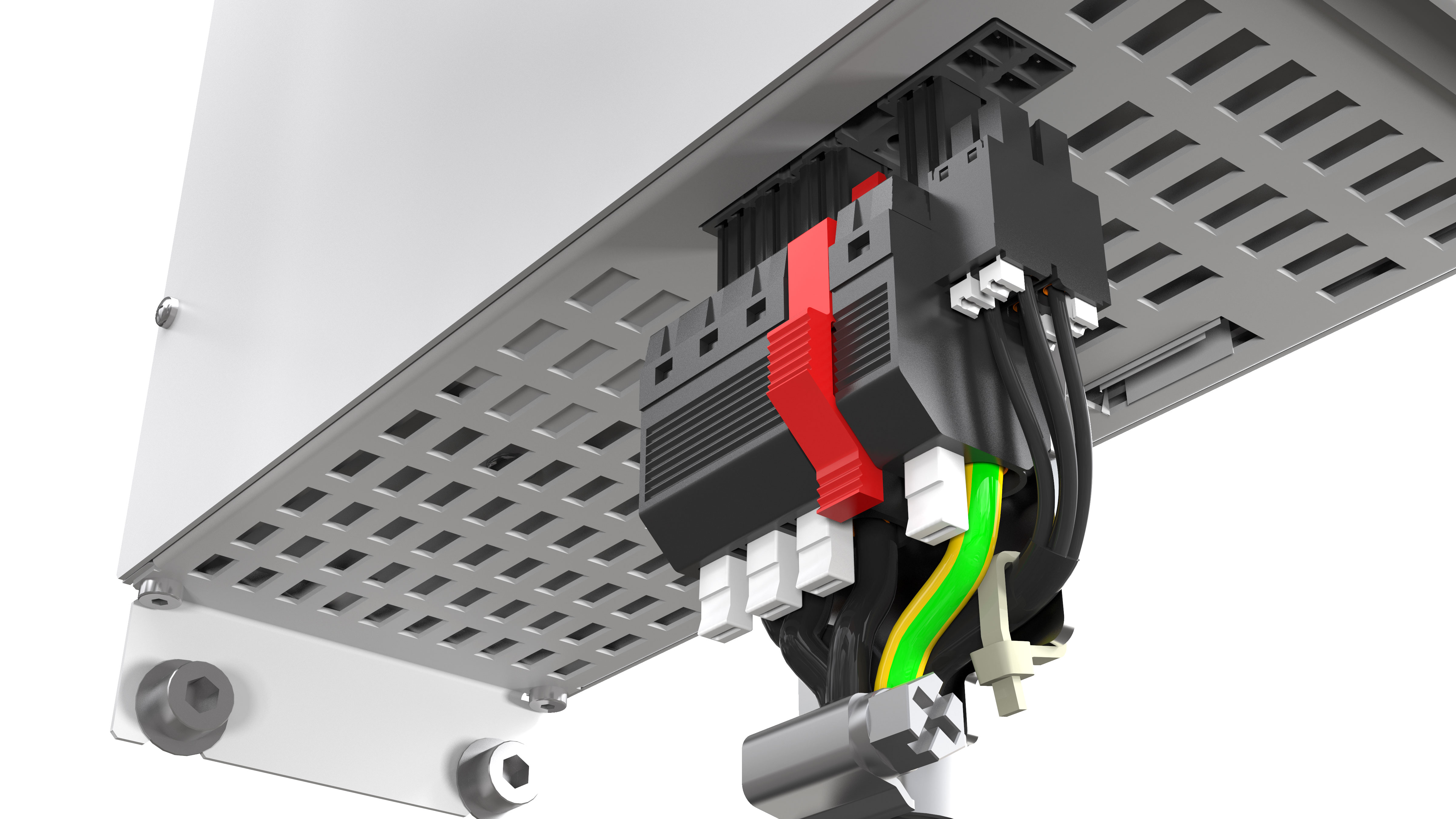

Single cable solutions between motor and drive controller

Consequently, it follows that a cable is fitted with one plug-in connector or connection on the motor and one on

the drive. M23 circular connectors have proven effective on the motor side, unlike on the drive side where the

cable has often been split and routed to two plug-in connectors. A logical solution here is of course hybrid

plug-in connectors.