Optimizing efficiency is at the heart of production; fast, reliable, and reproducible production processes are

essential. Automation offers the opportunity to make production processes more efficient, and digitalization is

the tool par excellence for this. Digitalization offers ever new, faster ways to simulate traceable production

processes and implement them in the next step.

However, digitalization also helps to accompany the complete life cycle of machines, plants, and production

facilities. There are opportunities for "remote" commissioning, early detection and addressing sources of error,

and continuous optimization of processes.

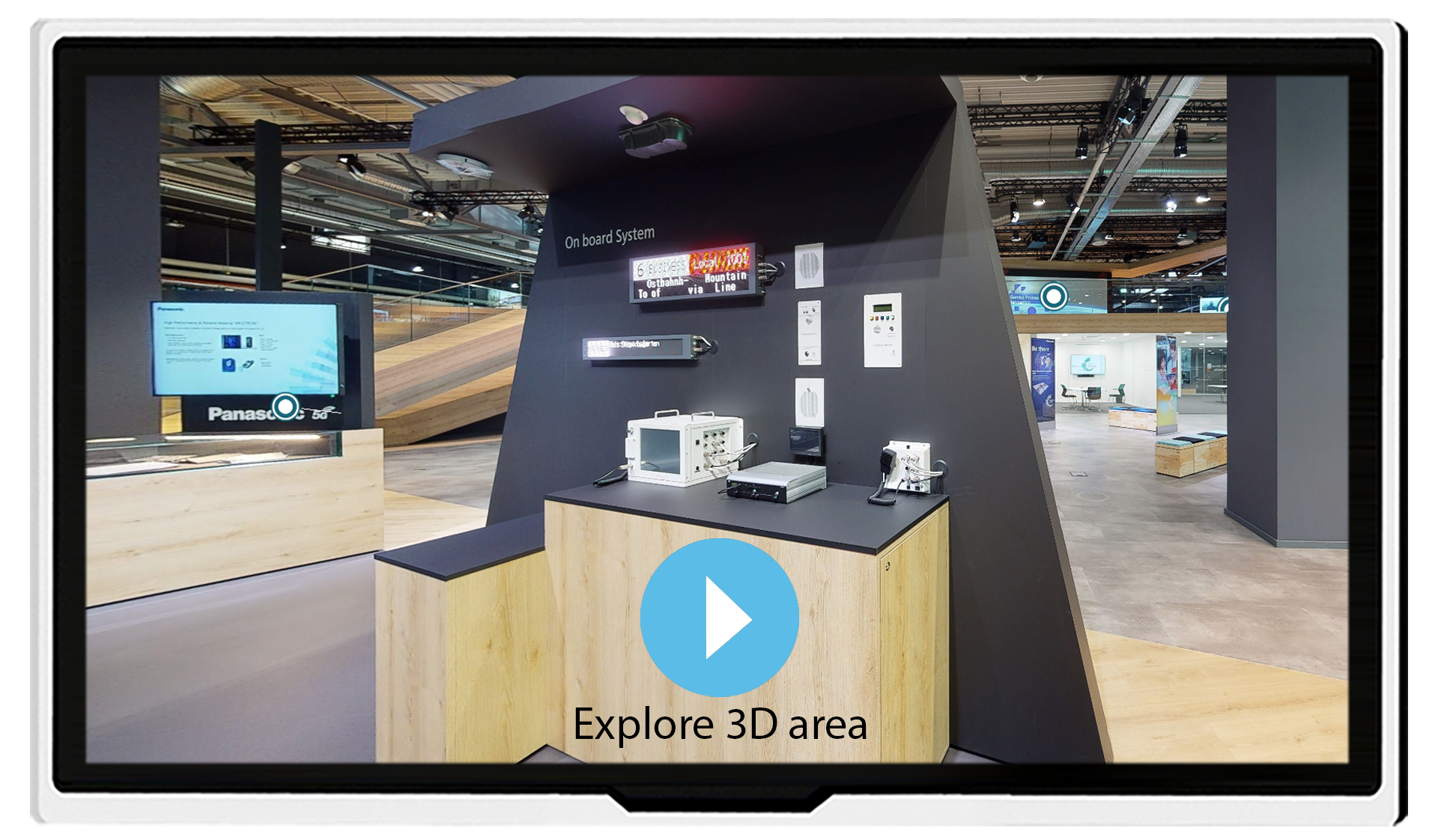

It, therefore, seems only logical that Panasonic Industry Europe has opened a Customer Experience Center in the

spring of 2021 on around 6,000 square meters, allowing everyone to experience innovations and high technology

haptically, on-site, and firsthand.

Showing innovative solutions for different industries under one roof and making them public as a place of

experience is a step that Panasonic Industry Europe has deliberately chosen.

The Panasonic Campus Munich with

the Customer Experience Center is neither an in-house exhibition nor a museum or archive for products and

developments. Instead, the Customer Experience Center in the heart of one of Bavaria's most important technology

locations is a center of encounter, a meeting place of ideas, around which service centers, laboratories, and

development departments are grouped to work creatively on new, even unconventional approaches to solutions, to

use synergies and to focus on concrete added value for customers. Here, in the heart of Europe, our engineers,

trainers, and service staff are already working together with our European customers on the answers to

tomorrow's questions. Closely aligned with the needs of our partners, the Customer Experience Center enables us

to bring this innovative strength to life, visualize the synergies of the Panasonic Corporation and bring them

to the European production sites in the form of concrete solutions.

Five subareas that illustrate this approach of centrally bundling competencies are, for example, the

Intralogistics Competence Center for our IIoT Intralogistics (Logiscend) solution, the Laboratory for Industrial

Sensor Technology, the Center for Servo Drive Technology and Controls, the Laboratory for Laser Marking Systems,

and the Service Center for Factory Automation Solutions for our European customers.

Panasonic Campus Munich

Panasonic Campus Munich

Panasonic Customer Experience Center

Customer Experience Center

Panasonic Customer Experience Center

Customer Experience Center