Innovative technology / Sensors

Electromobility is one of the most significant trends in the automotive industry worldwide. More

and more automakers are turning to electric cars to reduce the CO2emissions of their vehicle fleets. Of crucial

importance for the success of electromobility is the efficient production of

battery cells. For this reason, carmakers are increasingly positioning themselves

as battery manufacturers alongside major suppliers.

It is true that the production

of car batteries is currently still concentrated in Asia.

In recent years, however,

Western companies have also invested in building up their own battery production capacities.

Short innovation cycles

The processes and technologies for the production of battery cells will further develop in the

coming years. Whether new raw materials, modified mixing and coating processes, or different

processes for calendering and winding, there will always be changes.

If battery cell manufacturers want to prepare existing and future production plants

for this dynamic phase and significantly shortened innovation cycles, they need powerful

automation partners who support the digital transformation with their solutions and thus

enable modular, flexible plant concepts.

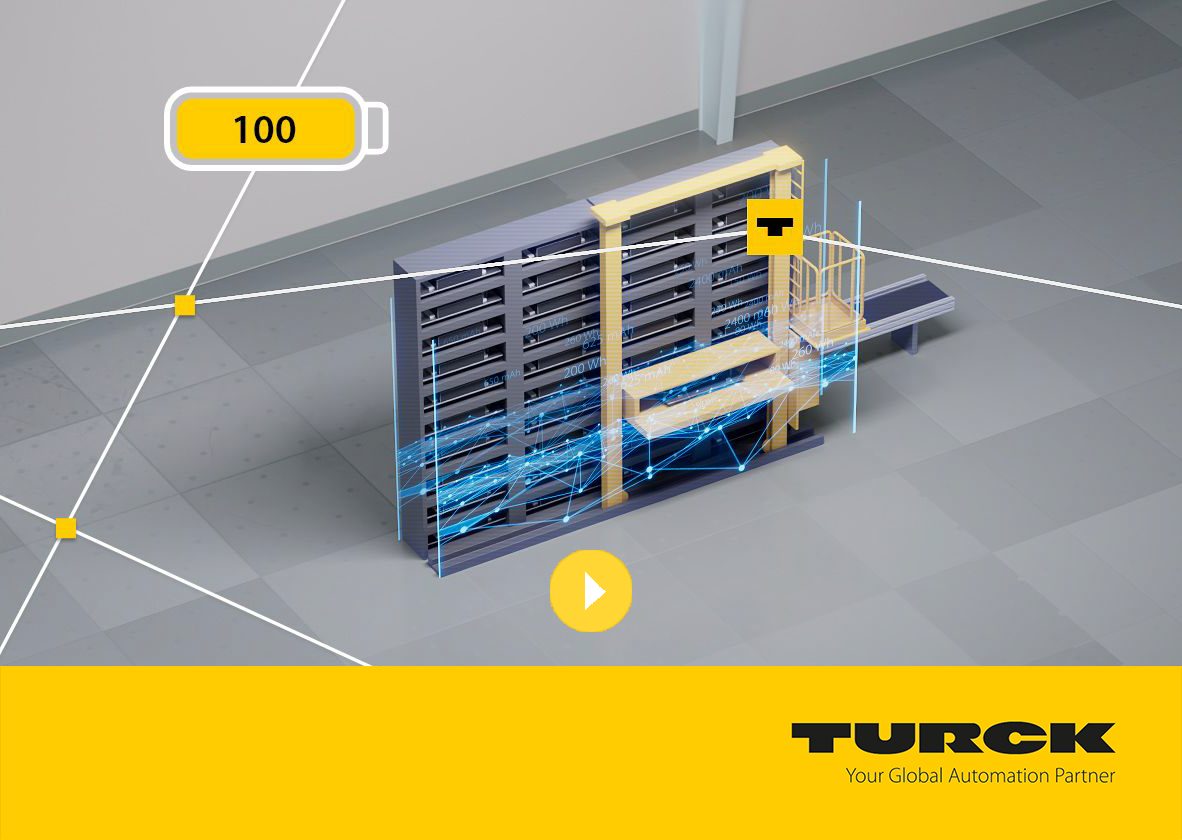

With its robust portfolio, Turck has been one of the most important automation partners

for the automotive industry around the globe for several decades – and today

the most successful battery manufacturers also rely on Turck technology and design

their production plants to be flexible and future-proof with data-driven process optimization.

Three loading columns for production efficiency

For example, contactless RFID identification technology helps to increase the output of existing plants

while at the same time improving process reliability and product quality.

Condition monitoring

solutions reveal problems at an early stage and thus enable predictive maintenance measures,

which permanently increases the availability and thus the overall efficiency of a plant (OEE).

Application example: The roller pressure during calendering is critical for the quality of the battery cells, Turck's fluid sensors continuously capture the measured values