Leakage current

Leakage current is the current measured flowing through the protective conductor to ground. If there is no

ground connection, it is the current that could flow to ground if a conductive path is present, which

includes the human body.

In modern residential and office applications, if that current exceeds dangerous limits, the Residual

Current Device (RCD) would trip, isolating the equipment or device from the AC source. Many people will have

experienced this if they have cut the AC cable while using a garden hedge trimmer.

For healthcare applications, the maximum limit for leakage currents is set much lower, depending on the type

of medical device being used. Medical leakage currents are not intended to be applied to a patient.

How does an AC-DC power supply generate leakage currents?

A certified medical power supply must comply with many other restrictions besides the leakage current

limitations. These include EMC (Electro Magnetic Compatibility) for conducted and radiated emissions, along with

immunity against voltage dips, electrostatic discharges (ESD), input transients, RF (radio frequency) and even

magnetic fields. Meeting these EMC standards is a legal obligation in many countries.

It ensures that electrical

and electronic equipment functions correctly in its environment and does not generate unacceptable disturbances

that could affect other equipment.

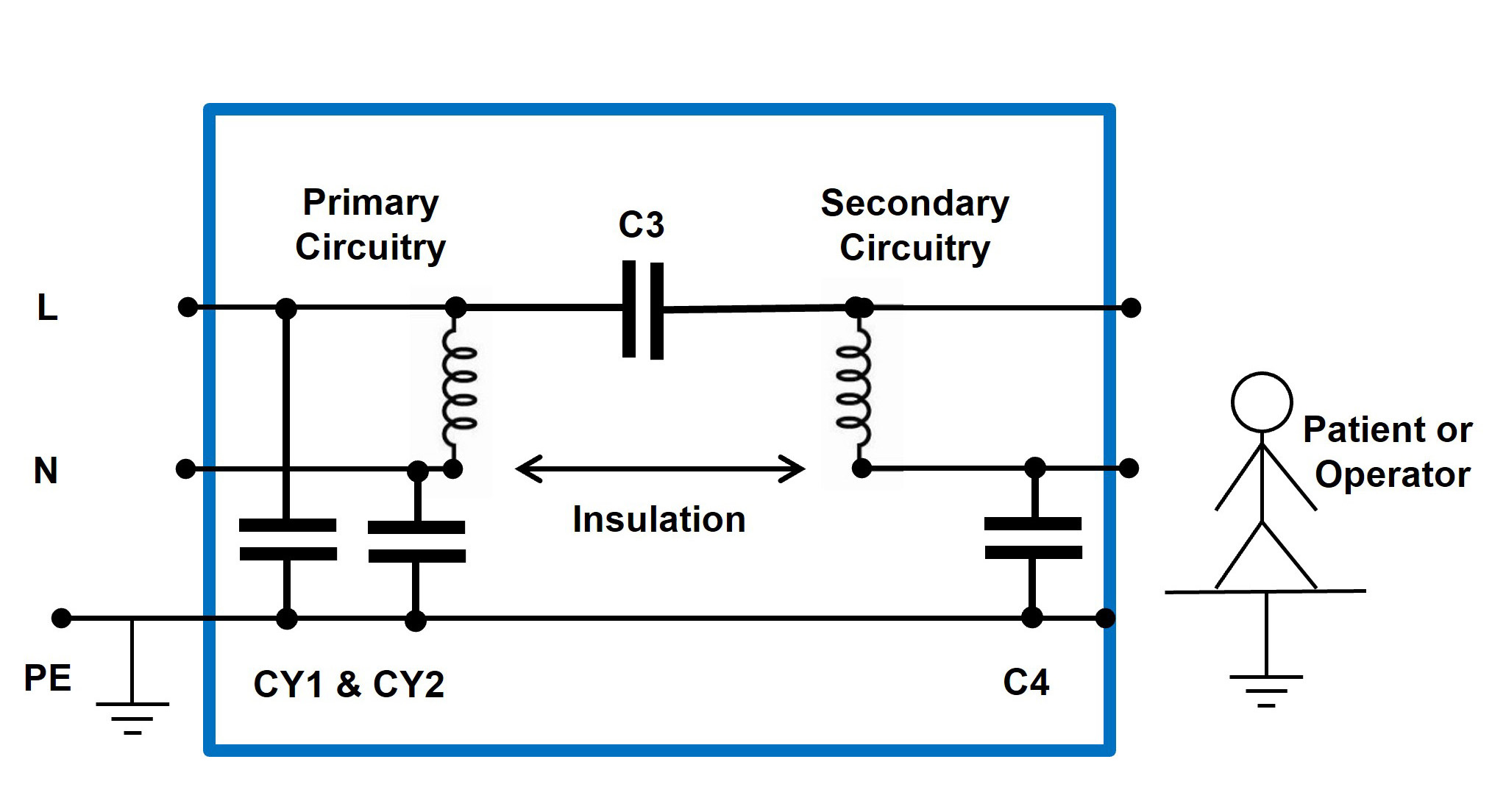

Power supplies use high frequency, high voltage switching circuits, typically operating between 40 kHz to over

500 kHz. These circuits generate high frequency electrical noise. To pass the conducted and radiated emissions

standards, filtering circuitry is required. Ceramic filter capacitors are used to reduce electrical noise

(Figure 1).

Capacitors CY1 and CY2 are used in conjunction with filter inductors (not shown). High frequency noise is

diverted away from the AC source, through the capacitors into the earth ground (Protective Earth) connection.

This technique avoids interference with other equipment also using the AC feed.