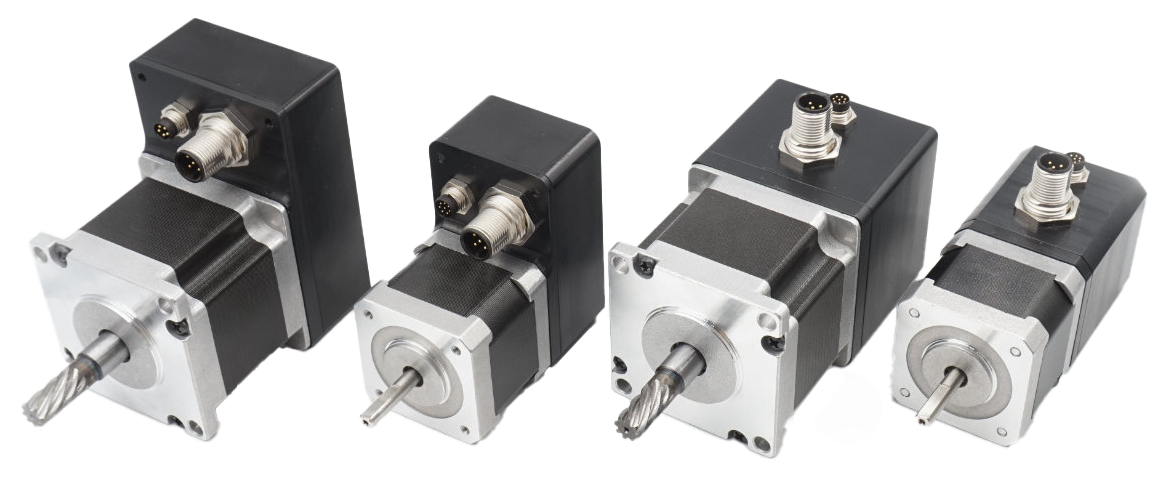

KSS is a manufacturer of ball screws and actuators (sales Dynetics),

especially for miniature sizes with a shaft diameter of 16 mm or less.

Recently, KSS introduced precision rolled ball screws of the PSR/PSRT series, which achieve

an accuracy of less than 0.005 mm (tolerance class/accuracy class JIS C5). They feature steel

balls that provide rolling contact between the nut and lead screw, achieving a mechanical

efficiency of about 90 per cent and reducing the required torque to less than one-third that

of conventional lead screws. The design of the KSS ball screws also makes it easy to convert

linear motion into rotary motion.

The design of the KSS ball screws also makes it easy to convert linear motion into rotary motion.

Dynetics also has stainless steel rolled ball screws (SSR series) in its range. Classic rolled

ball screws can achieve accuracy class Ct10 or Ct7. Ct7 achieves an axial clearance of 20 microns

or less. With Ct10, an axial play of 50 micrometres or less is possible.

Dynetics has two types of lead screws in its range: the integrated version with

a larger end tang (PSRT) and the fully threaded version (PSR). In the integrated

end trunnion version, the fixed end trunnion can be set larger than the nominal

diameter of the lead screw so that no interference fit of the sleeve is required.

The profile and dimensions of the end journal are standardised so that the KSS

Compact Support Unit can be installed. As the support-side end journal is unmachined,

it is possible to carry out additional finishing with the thread length required by

the customer. Special end journal profiles are possible as a special design.

The fully threaded version scores with a good price-performance ratio. The axial play is set to 5 micrometres or less, a play-free version (preload) is possible on request.