Ready for large volumes of data

A leading railway system integrator in Asia employs Cincoze’s DX-1100

embedded computer as the central platform for its PCMS. The DX-1100 processes

large volumes of camera and sensor data in real time, enabling precise monitoring

of pantograph operation and current transmission. In the event of a fault, the

Train Control and Monitoring System (TCMS) is automatically notified, while the data is

simultaneously transmitted to the control center to support fault diagnostics and

predictive maintenance. This significantly increases both the reliability of the

power supply and the operational safety of the train.

Principle of intelligent pantograph monitoring

Which features lead to the use of the DX-1100?

When selecting a box PC for demanding railway applications, a number of features need

to be considered. The most important are outstanding computing performance,

railway-optimized I/O interfaces, robust design, and professional certifications.

In all these respects, the DX-1100 has proven itself.

Outstanding computing performance

The PCMS generates large volumes of image data during train operation.

The DX-1100 supports Intel

® Xeon

®

and Intel

® Core

™

9th/8th Gen processors and accommodates up to 64 GB of memory, making it ideally

suited for real-time processing and analysis of critical imaging data.

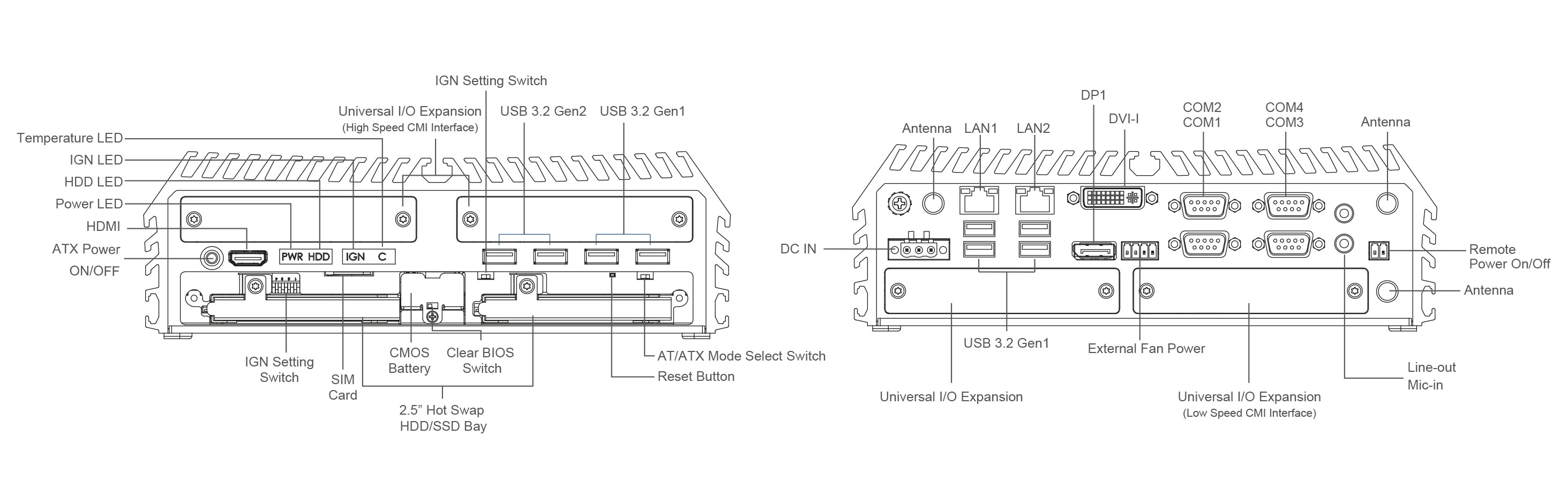

Two front-accessible 2.5-inch SATA HDD/SSD trays with support for

RAID 0/1/5/10 enable fast data access and high data security.

With its compact

dimensions of only 242 × 173 × 77 mm, it is particularly well-suited for

installation in confined spaces such as onboard electrical enclosures.

This provides an optimal combination of computing power and installation flexibility.

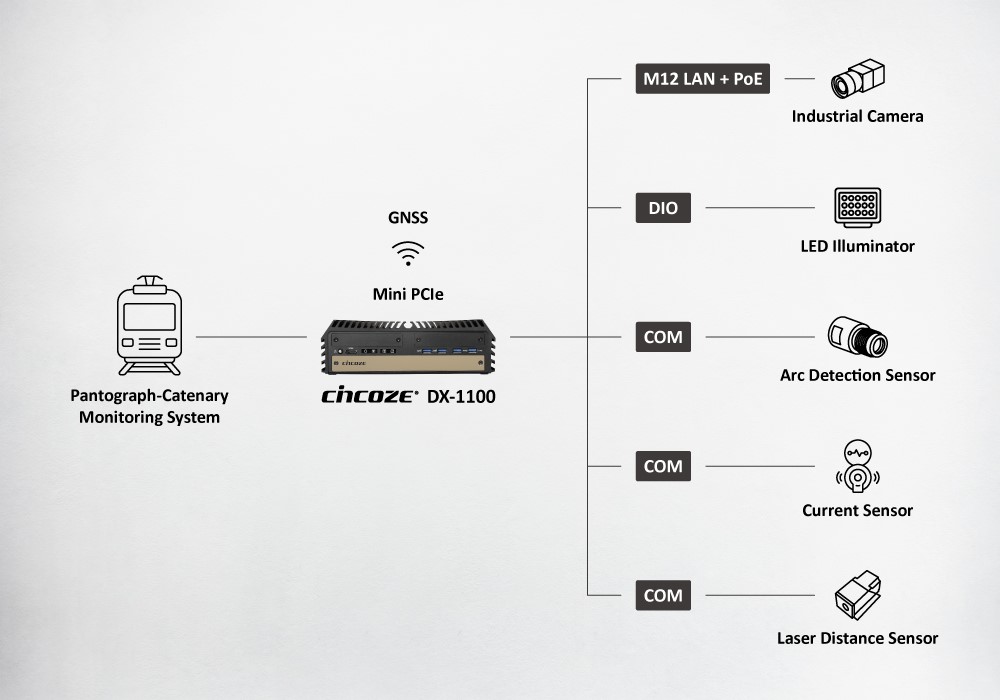

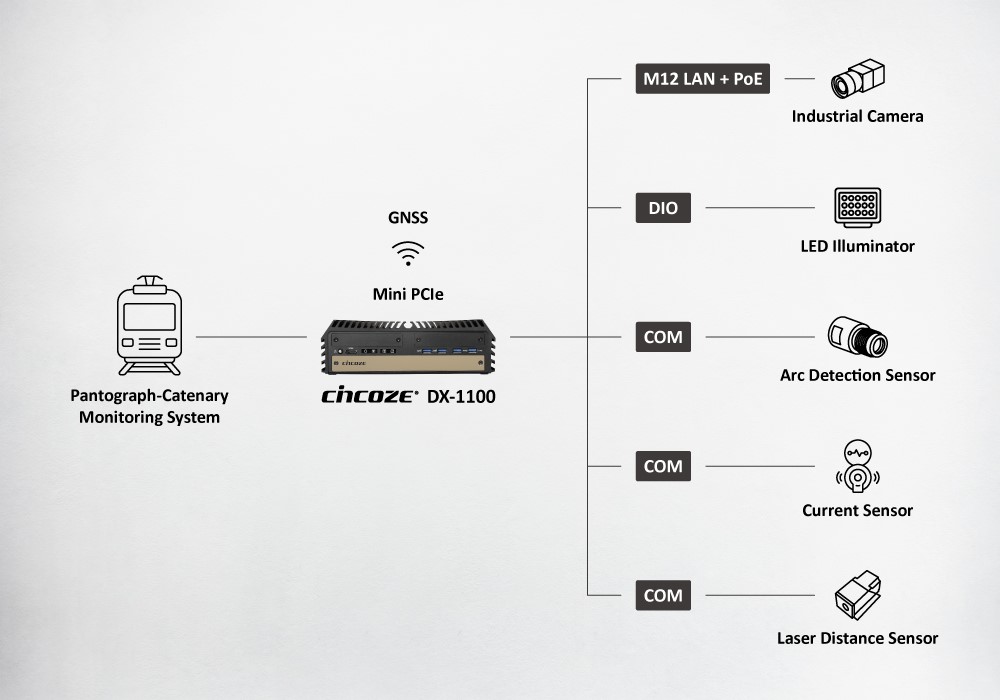

Railway-optimized I/O interfaces

The DX-1100 offers a wide range of I/O interfaces to meet all connection

requirements of the monitoring and sensing equipment used in the PCMS.

It supports up to eight M12 LAN ports with PoE, ensuring stable connectivity for industrial and

thermal imaging cameras.