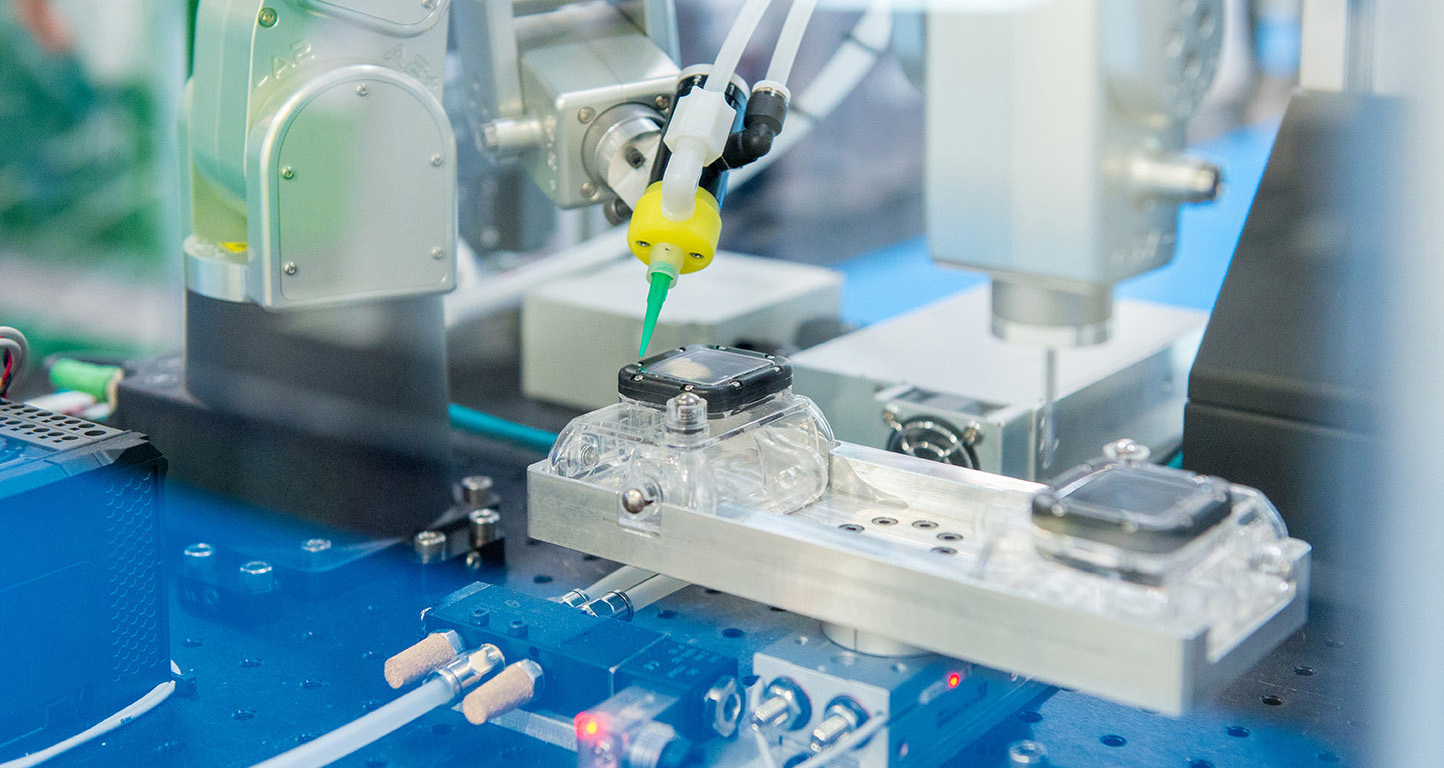

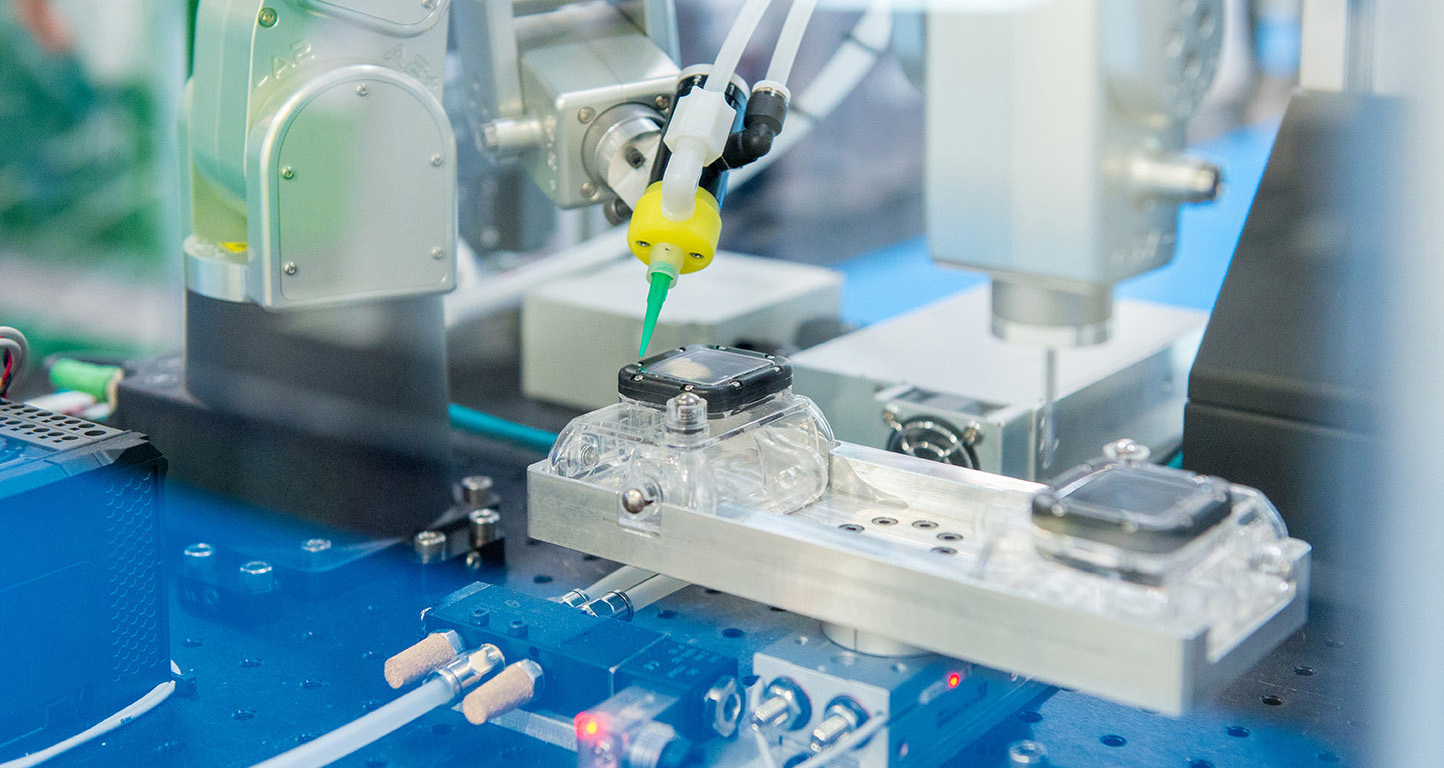

Precise gluing

Mecademic recently turned six, but it was only in May 2016 that the first Meca500 was delivered to industry.

Extremely compact and precise, and much smaller than any other six-axis industrial robot arm, the first

Meca500 was implemented into a sophisticated vision-guided microsurgery system.

But designed as a 6D

positioning component, rather than a complex stand-alone system, the Meca500 is particularly easy to

integrate in both intricate and simple automation projects.

Handling small parts

Thanks to its unchallenged advantages, the Meca500 gradually became the indisputable choice for precisely

handling small items, weighing less than 500 g. So far, some 350 units are in operation in some 24 countries

around the globe. The vast majority of these robots are used in automated inspection and test

applications,

but many Meca500 are also used for assembly or gluing, or for academic purposes.

Technical details of the robot

Its controller is embedded in the robot’s base. The Meca500 comes with a small external power supply with

safety features.

Most importantly, however, the Meca500 is very simple to integrate. There is no proprietary

programming language to learn, just a set of robot related instructions, which are sent to the robot by a

PLC or a computer via the TCP/IP or ETHERCAT communication protocols.

Furthermore, the robot comes with a web interface for operating it, and there is no software, no API, no

SDK, that has to be installed.

Two new robot arms in development

This year is set to be a major milestone for Mecademic. The company moved into a 10,000-square-foot facility

near downtown Montreal, where it is planned to double the team. Mecademic started to significantly ramp up

its

production capacity with major equipment acquisitions such as a 5-axis automated machining center and a CMM

that

will be used robot calibration. Finally, Mecademic will release two new robot arms.

▪ ds

Exact gripping of small parts on the assembly line