Test without a trace

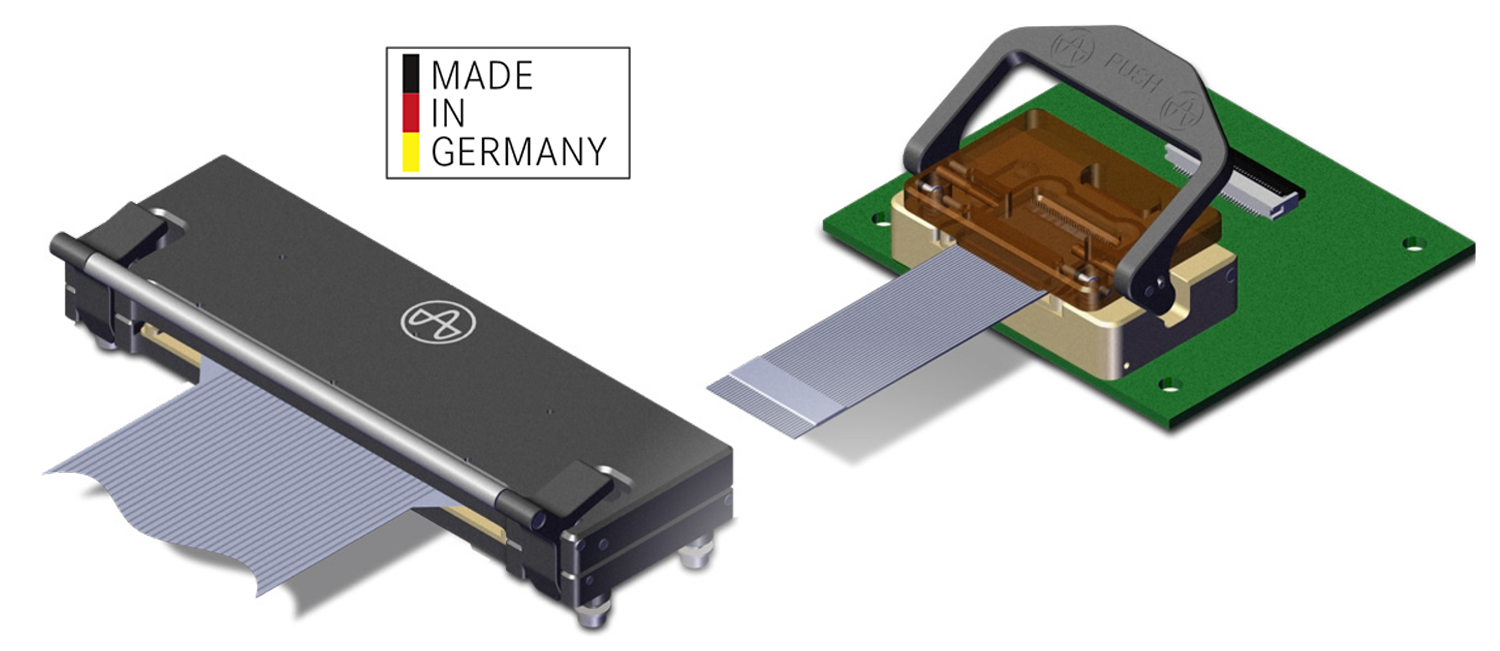

The probe pins only touch the material at a tiny point and only apply enough pressure to make a secure

connection, but the material will not be deformed. The vertical placement of the pins causes no scratches,

furrows or grooves and the Device Under Test (DUT) leaves the test socket almost without trace.

From 0.3 mm Pitch

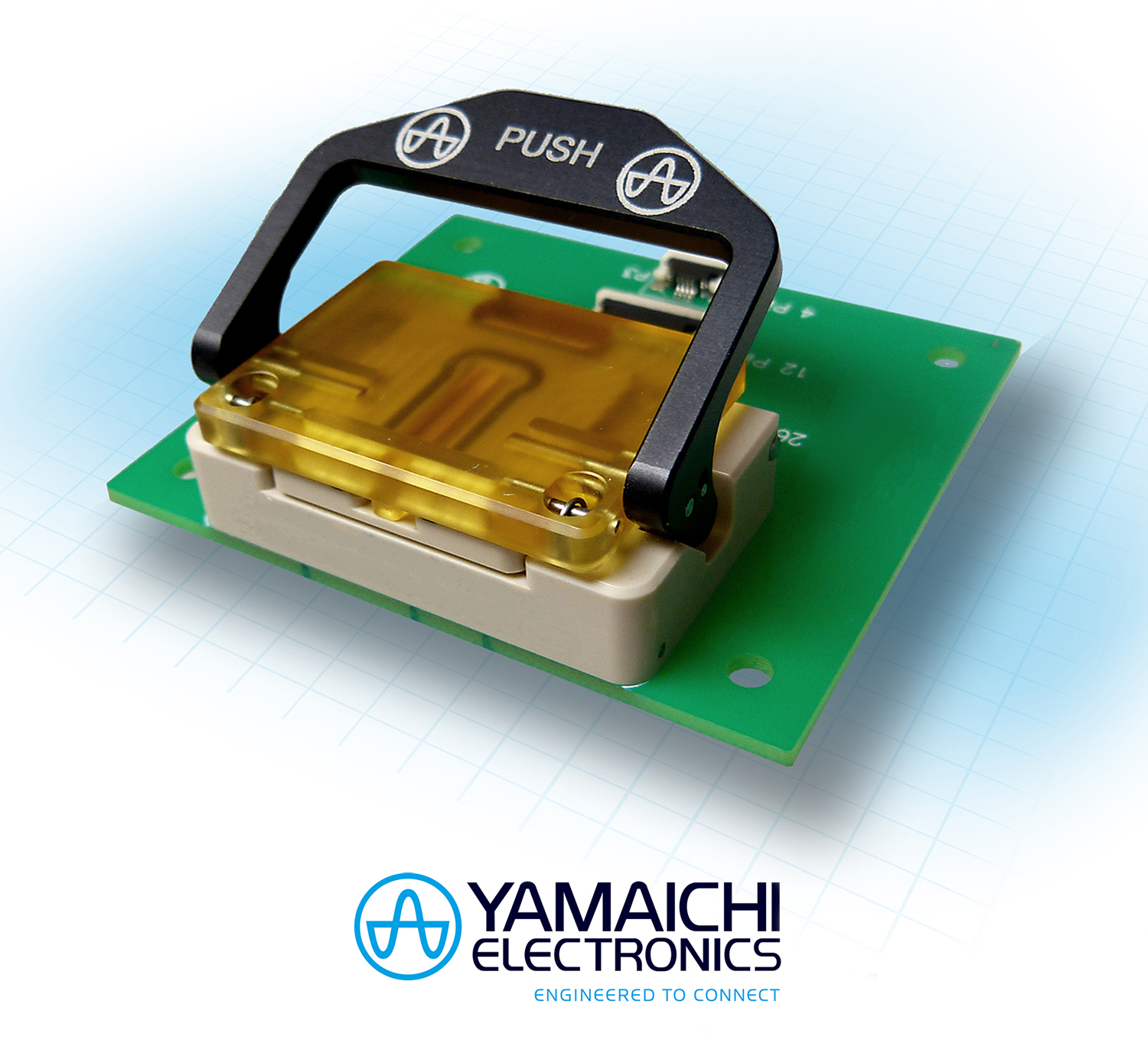

More and more contacts in less and less space require the highest degree of precision. Yamaichi Electronics

specialises in high-precision test solutions and offers test sockets from a pitch of 0.3 mm in the highest

material and production quality.

Best Materials

Yamaichi Electronics uses only high-quality materials for its test sockets. The housings are made of PEEK

and anodised aluminum. The individually tested probe pins are made of a beryllium copper alloy coated with

nickel and gold. For special requirements also pins with other surfaces can be used.

Extremely durable

Yamaichi Electronics guarantees up to 50,000 mating cycles for each FPC/FFC test socket. The test sockets

are adapted to the customer needs. Upon request, the right PCB is delivered as well.

▪ ds