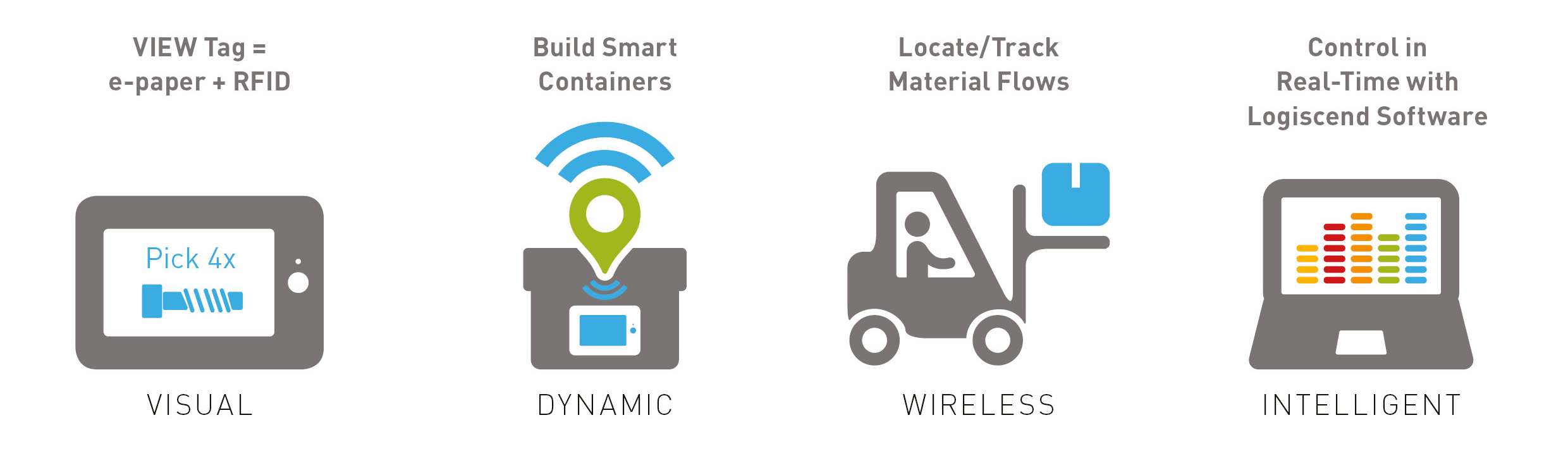

Industrial IoT for material flow control: paperless yet readable

With the hardware and software of the Logiscend material flow management system, Panasonic enables complete

end-to-end solutions for the control of containers, materials, and goods movements. Smart Panasonic View Tags

combine the best of both worlds as intelligent IoT labels that combine the advantages of visual identification

on the container with the strengths of automated, IT-based track & trace through embedded RFID transponders. In

this way, effective solutions for efficient and error-free intralogistics can be set up for employees and IT

systems alike. And all completely paperless.

Logiscend’s modular software supports smart work processes, from replenishment requests via View Tag clicks to

an intelligent container, inventory, and WIP management, as well as the transmission and visualization of

container-specific work instructions on the View Tag's electrophoretic (e-paper) display. Specifically, a pilot

project will begin early in 2021 at the Siemens site in Görlitz, Germany. It will digitize the flow of goods at

the Siemens Energy headquarters for technology and process development. The Logiscend software and View Tags

hardware will be tested over a period of six month with the material flow management converted to paperless

logistics. Further locations are under evaluation.

Material flow control

Material flow control