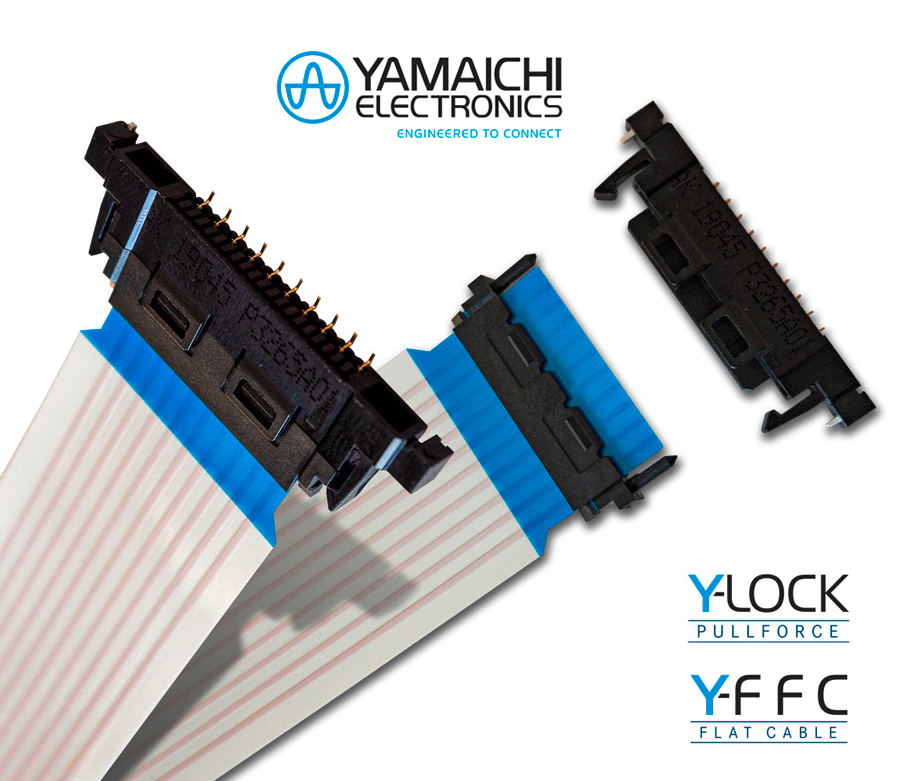

The Y-Lock series is a board-to-cable system and available in three different versions. In the last years, the

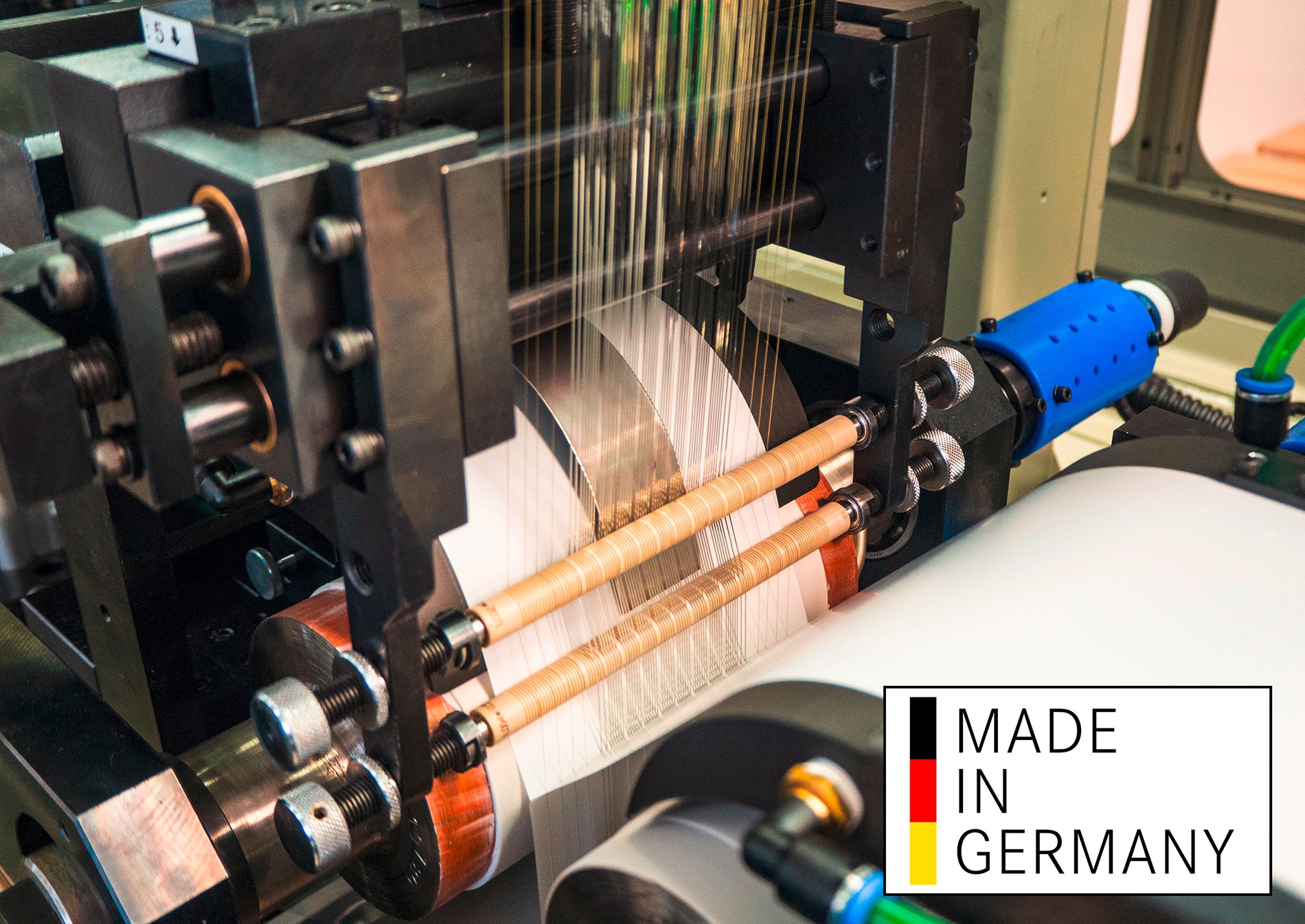

renowned system has proven itself. It is successful in diverse automotive applications. The FFC (Flexible

Flat Cables) suitable for the connector are produced in Yamaichi Electronics‘ own factory in Germany.

The non-ZIF-based connector system is especially outstanding for its locking system, which works without

opening or closing a flap or drawer and without actuating an unlocking mechanism. In the current version 1,

the interlock is provided with a ratchet hook on the housing of the connector, which engages behind the

supporting tape of the FFC/FPC. Both contacting and removal of the FFC are very simple using a defined

pull-out force.

Positive features of

version 1 retained

The Y-Lock version 2 retains all the positive features of version 1, but also offers some interesting new

features. An additional plastic stiffener has been added that is mechanically assembled with the FFC. The

stiffener then engages with the connector. This new system makes guiding the FFC and inserting the FFC into

the connector more convenient. The pull-out force for the FFC has also been increased from about 10 N to about 25 N.

Another advantage of the Y-Lock series is the greatest possible security of the contact coverage between FFC

pads and connector. The contact coverage is provided by the FFC guide rails in the connector. This

facilitates even more the FFC guiding by the stiffener which positions the FFC. That makes it simply

impossible for the FFC to be crooked, which is always a possibility when using ZIF connectors. That means

there is no danger of a lack of contact coverage.