Not having to send out a service technician can mean savings of EUR 1,000 or more. However, remote

maintenance is not only important for analysing and correcting errors: It is also beneficial for setting up

and maintaining the plant, as well as for carrying out optimisation work.

Optimise the capacities

of specialists and reduce downtimes

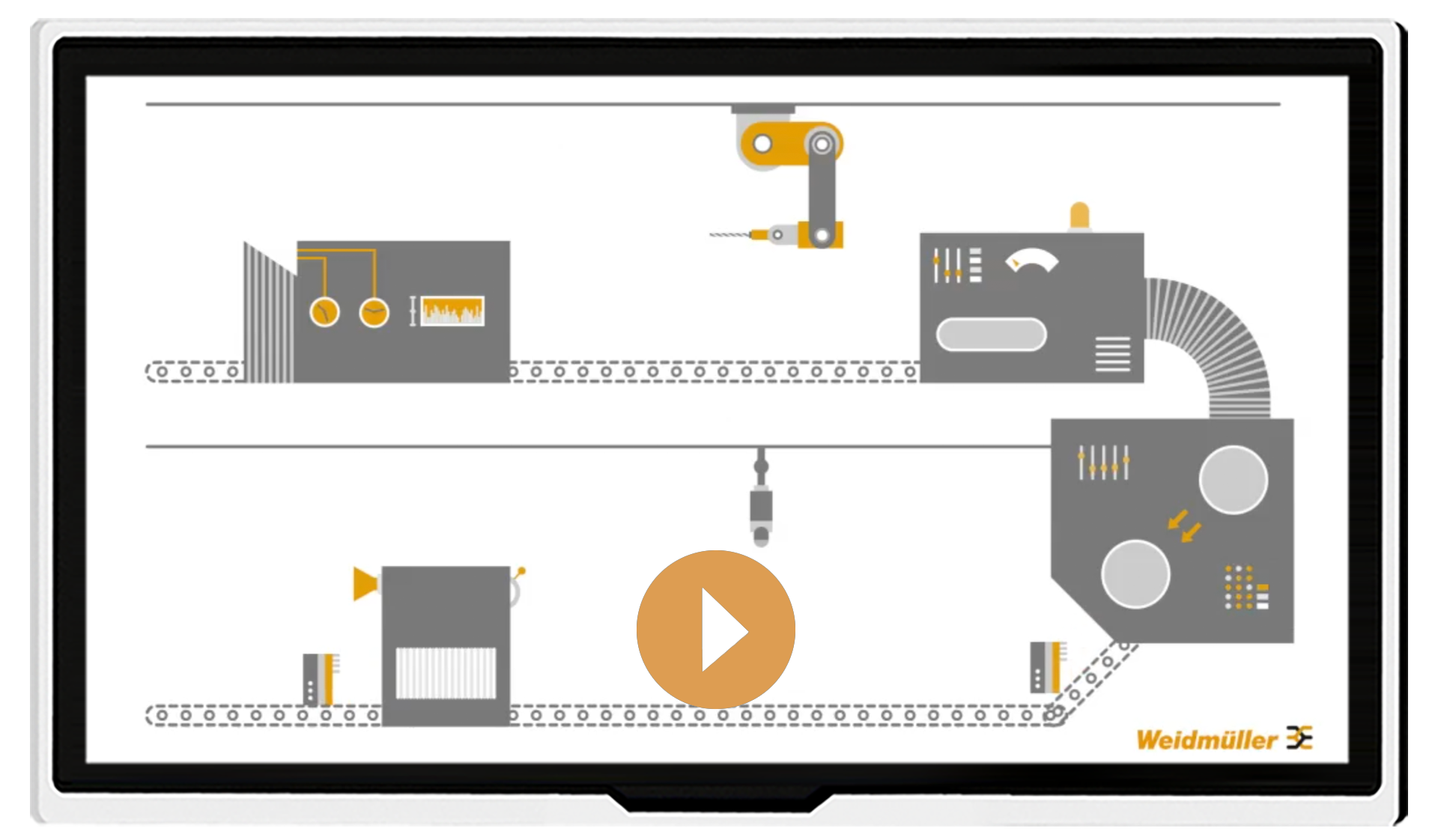

New technologies, digitalisation and increased customer requirements lead to increasingly complex products.

In order to be able to produce these competitively in the globalised world market, production facilities,

buildings and even energy generation are becoming increasingly smart and networked. The mix of technologies

means that more people are involved in projects and are becoming increasingly specialised. This means that

employees' capacities are limited. During initial setup, a malfunction or optimisation work on the plant,

service employees must be present on site to cover their respective area of expertise. In the meantime,

often they are unable to work on other projects. The availability of the specialists as well as any

necessary journeys to the plant cost both time and money. This results in long downtimes, high costs and

dissatisfied customers.

Remote assist / remote access

gathering momentum

To meet the above challenges, companies are increasingly turning to remote access applications. Remote

access allows a company to access a computer or a network remotely via a network connection – on a worldwide

scale across national borders. This allows users to access the systems they need, even though they cannot

physically establish a direct connection.

In other words, users access systems remotely via a

telecommunications or internet connection. Time-consuming journeys are no longer necessary, malfunctions can

be rectified quickly and easily, which reduces downtimes, and plant optimisations can be carried out with

ease.

System essentials

In addition to the high security standards, the usability and flexibility of the remote access system are

also important. It should be possible to carry out the configuration easily and independently. Ideally, the

system offers a clear overview of the plant in the field and the connection is established with a single

mouse click. The remote access devices are connected simply by entering a code.