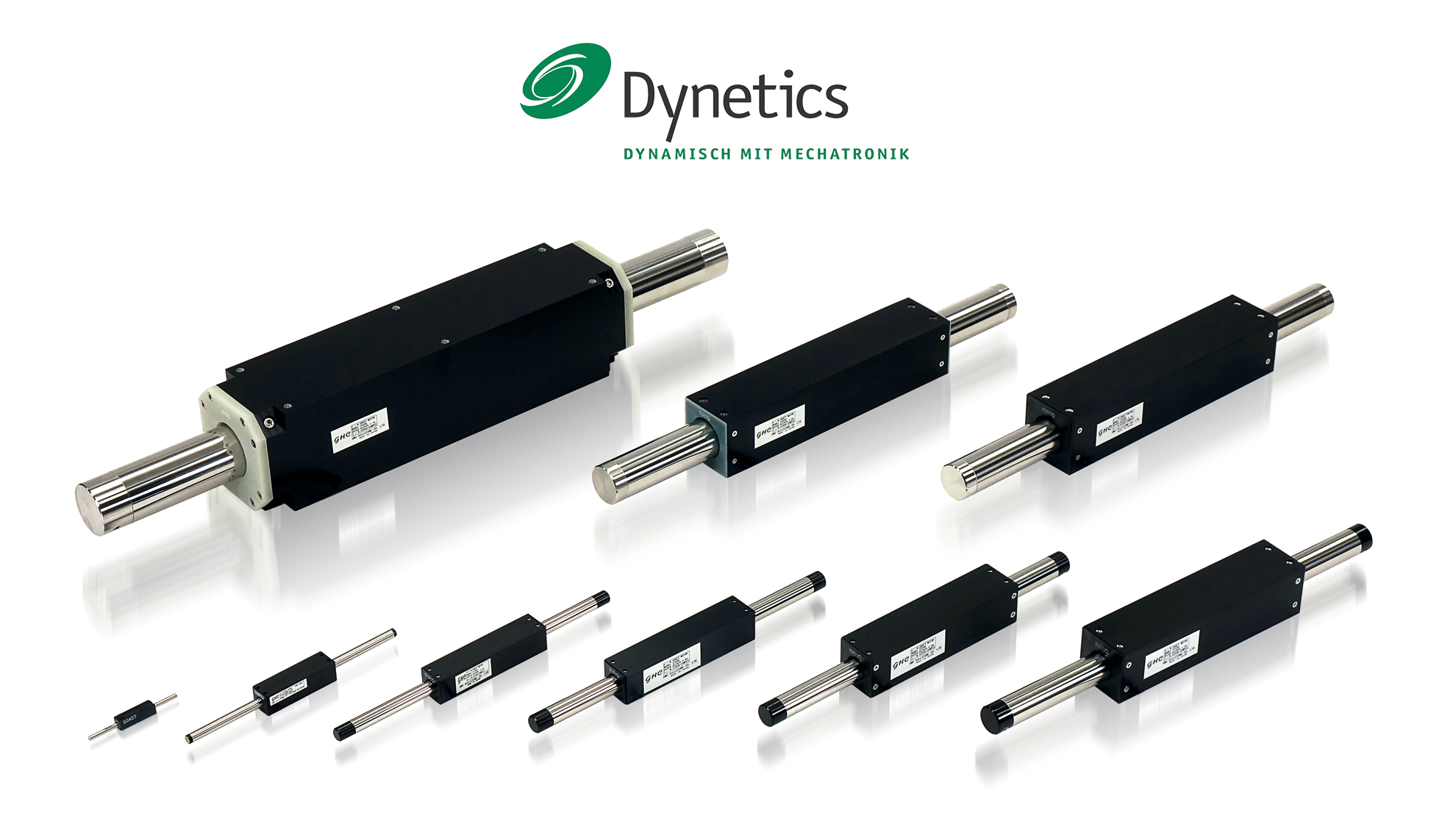

Linear servo motor for applications

with limited space

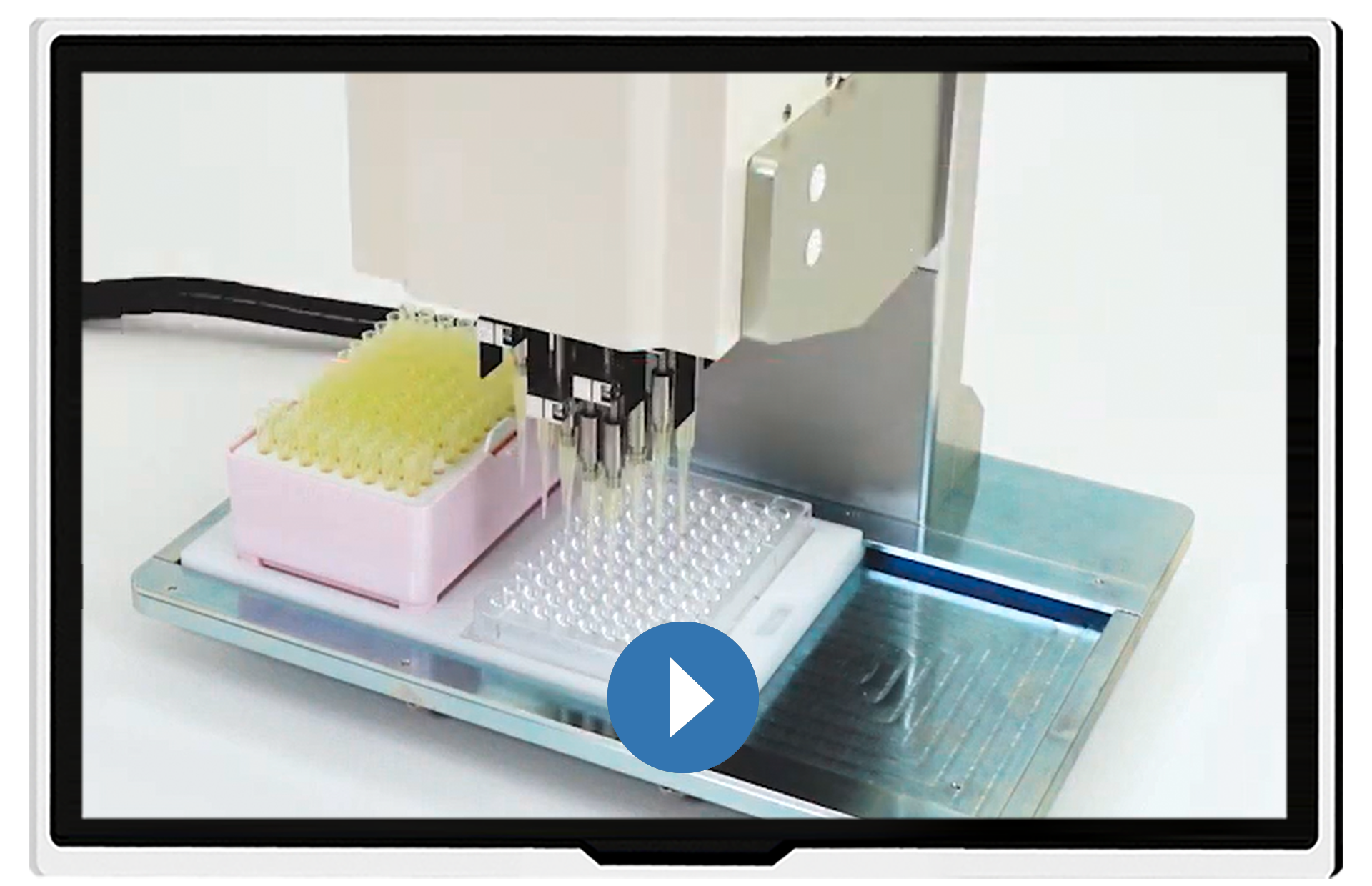

Reference design for laboratory pipetting robots

Nippon Pulse Motor (NPM), represented by Dynetics, has extended its linear servo motor series with a

very compact version. This series is suitable for applications with limited space – for

example in designs with 9 mm pitch.

The miniature linear motor of the SX060 series offers a torque of up to 14 Nm. Dynetics has realised a

reference design for computer-controlled pipettes with eight simultaneous channels with the SX060 linear

servo motor. The reference design is an example of how a flexible system with individual, reproducible

pipetting channels can be constructed, allowing the processing of individual pipettes to be easily automated

and providing optimised throughput.