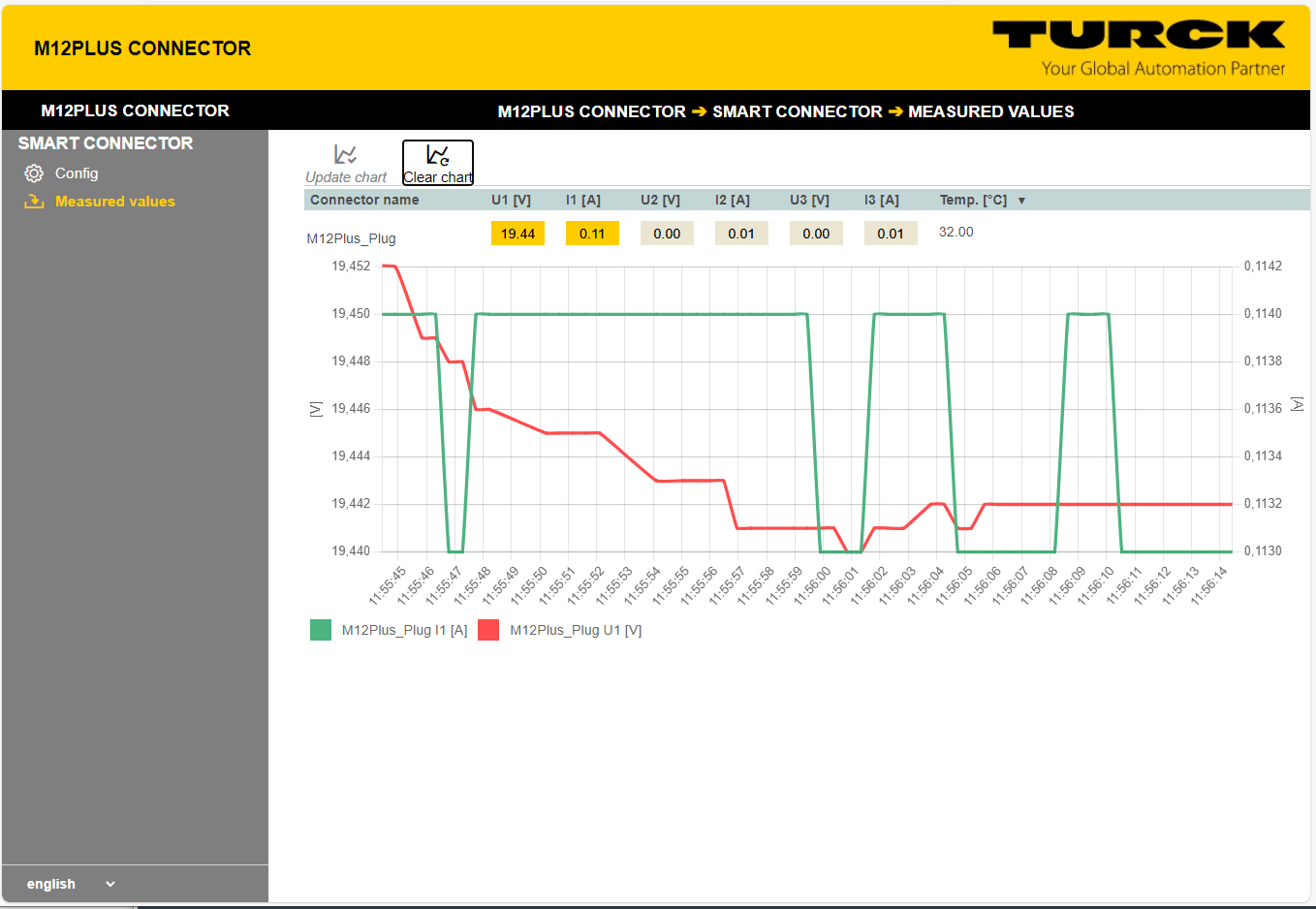

The browser-based Turck Automation Suite TAS graphically displays the measured values of the M12Plus

Besides the incorporated measurement technology, the M12Plus also features an onboard Bluetooth

chip. This enables it to measure voltages and currents and send these measured values to a data

interface in the plant, such as Turck's TBEN-PLC. A Bluetooth dongle enables the robust IP67

controller to read a host of Bluetooth-enabled devices, and the scan intervals can be adjusted

for the particular application in order to ensure optimum performance. The cable data is

transferred to the controller in real time. This information can be used to determine

potential issues such as voltage drops in the cable or the plug contact, even before the

connection actually fails. If required, the controller can be programmed so that an alarm

is triggered as soon as a specific threshold value is reached.

Effective protection from cable failures

The smart M12Plus connector with integrated measurement electronics consists of a

four-core cable (4 x 0.34 mm²) of the TXL series with a polyurethane outer sheath and

is specially designed for use in drag chains. A-coded M12 connectors are fitted to both

ends of the sensor/actuator cable. The integrated sensors enable precise voltage and

current measurement at the male and female connector.

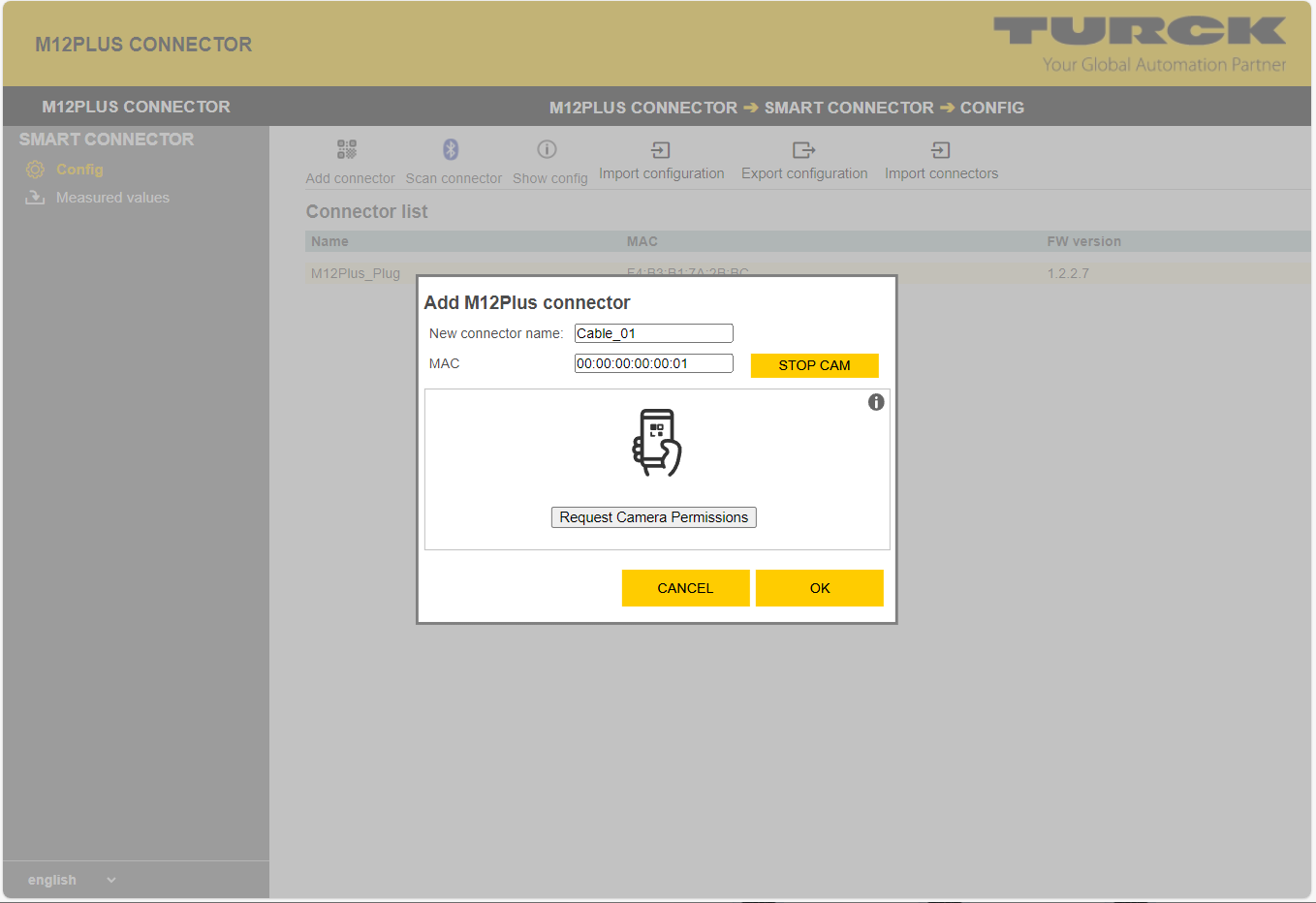

The M12Plus can also be configured conveniently

via TAS

Comparing input and output values thus enables problems such as cable kinks, cable

breaks or an inadequate power supply to be detected early on.

Video Expert Talk: M12Plus Connector

Fast localisation of failures

The measured values enable the precise monitoring of contact quality for reliable

connectivity. Factors such as contact corrosion or wear by repeated mating are taken

into consideration here.

The M12Plus also offers a decisive advantage in localizing

faults in the plant: the unique MAC address of each M12Plus connector makes it

possible to identify the cable at risk of failure directly via the documentation.