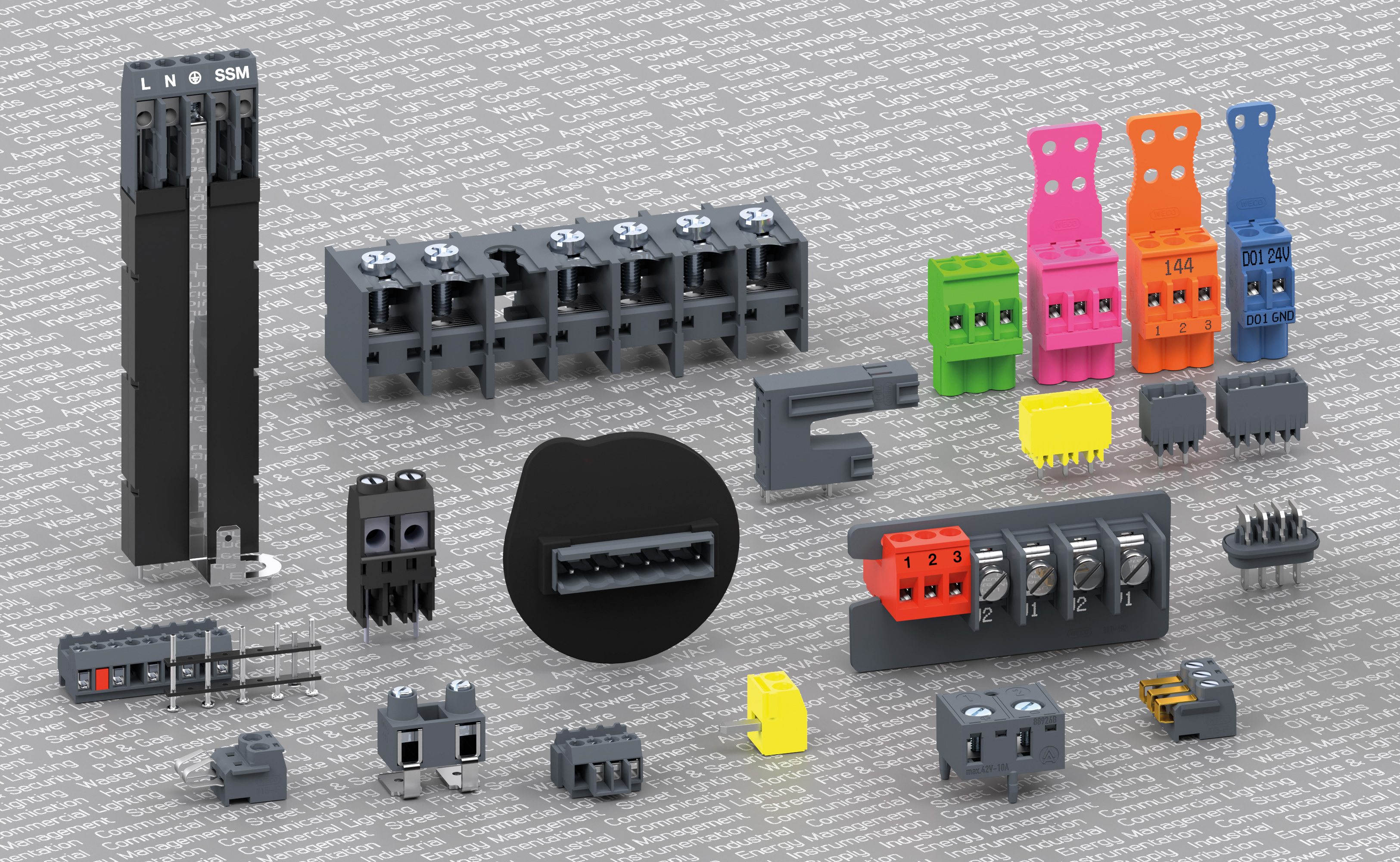

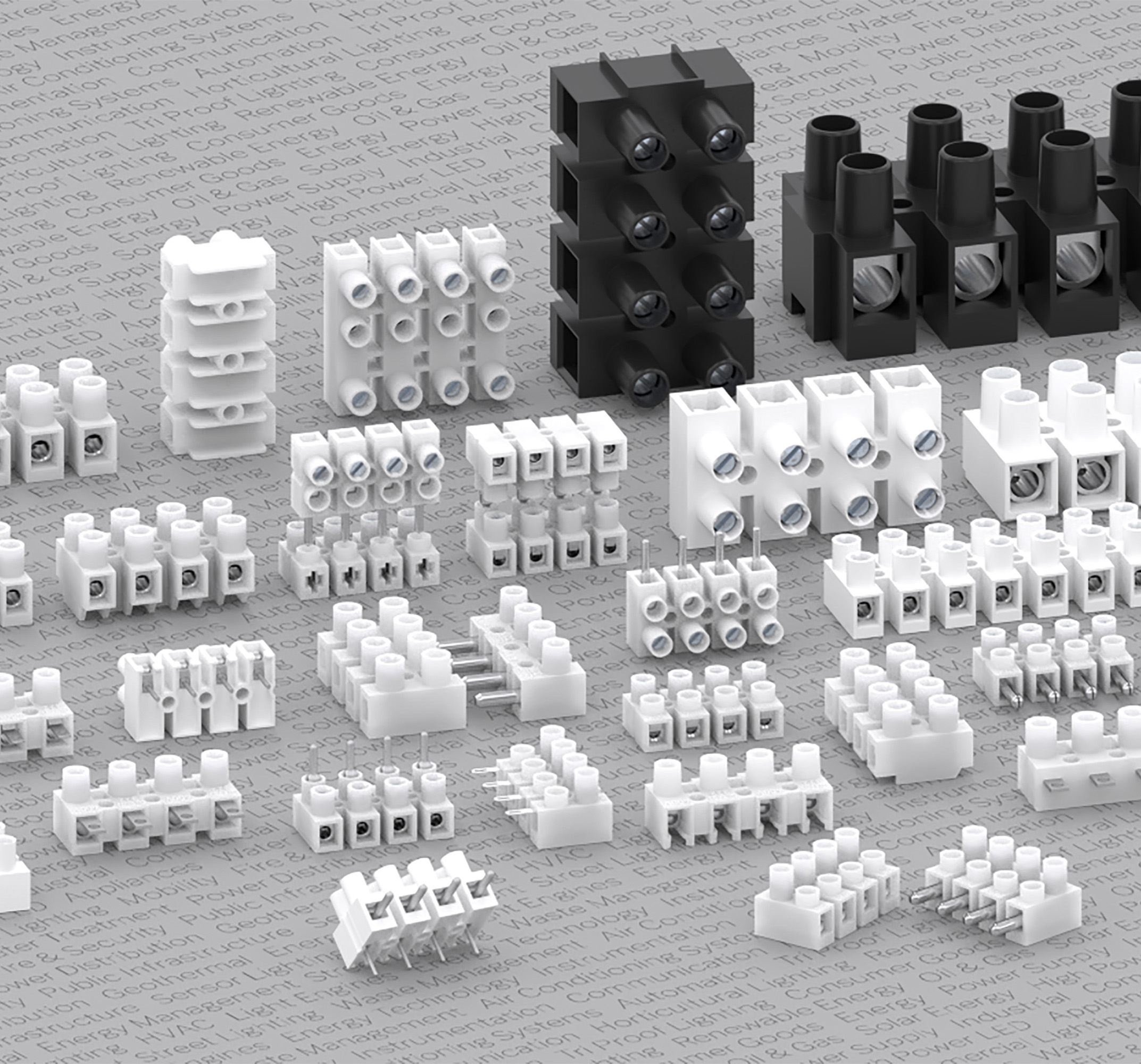

Housing colours, individual labelling or leading connector pins can be adapted to

the customer's requirements

In theory, wiring is simple: plug into the matching socket or onto the free-standing contact pins – and that's it.

In practice, unfortunately, it often is different because mistakes happen again and again.

Cables get mixed up, which can damage circuits and components if the wrong voltage is applied.

In the worst case, life and limb can even be endangered by incorrectly

wired devices. It also happens that plugs are twisted or plugged into the wrong,

unsuitable socket. Costly troubleshooting or even mechanical damage to plugs and sockets

can result in expensive follow-up costs. Occasionally, however, there are also special

constructional requirements that make an adaptation necessary.

For this reason, manufacturers of connectors and connection solutions often offer

the production of customised variants in addition to their standard range. This starts

with the individual labelling of cables and ranges from colour coding and simple physical

coding to customised shaping. These are also called Poka-Yoke solutions, after the Japanese

term for "avoiding unfortunate mistakes".